What is the difference between the front and side operation of diamond grinding wheel?

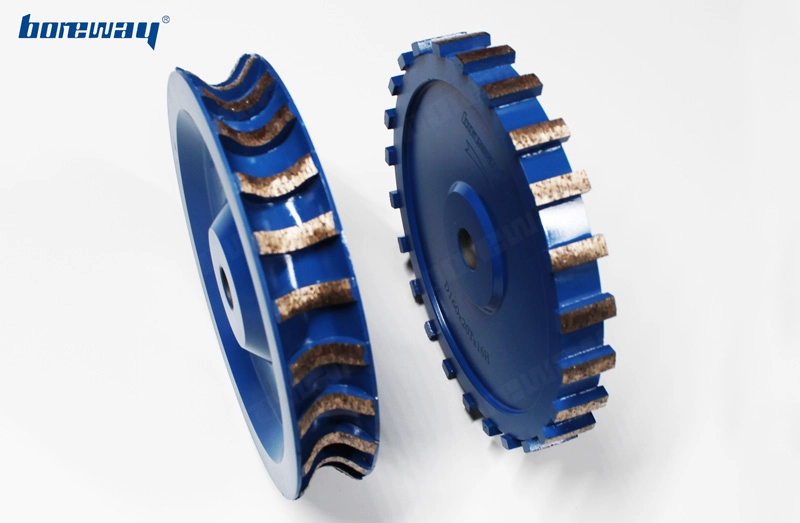

Diamond grinding wheel is a kind of circular consolidation grinding tool with through hole in the center, which is made of diamond abrasive as raw material, using metal powder, resin powder, ceramic and electroplated metal as binder respectively.

1. Side grinding:

In order to give full play to the role of diamond, we should try to increase the holding force of bond on diamond and improve the binding strength of grinding wheel. The single-layer high-temperature brazed superabrasive wheel can overcome the shortcomings of electroplated wheel, realize the chemical metallurgical combination of diamond, bond and metal matrix, and has high bonding strength. Only by maintaining the thickness of the bonding layer at 20% - 30% of the abrasive height, the abrasive can be firmly held in the high-speed and efficient grinding with large load, so that the exposed height of the abrasive of brazed wheel can reach 7 0% - 80%, which increases the chip holding space. The grinding wheel is not easy to block, and the utilization of abrasive is more full.

2. Front operation:

In daily use, many operators are always used to operate on the grinding wheel. Sintered metal bonded grinding wheel is made of bronze and other metals by high temperature sintering method. It has high bonding strength, good formability, high temperature resistance, good thermal conductivity and wear resistance, long service life and can bear large load.

Diamond wheel is a valuable tool, which is only used to process high hardness materials, rather than general steel or other soft materials.

The machine tool with diamond grinding wheel has better rigidity, higher accuracy of spindle selection (radial runout no more than 0.01mm), and micro infeed.

The diamond wheel of boreway belongs to the super hard abrasive wheel, which can grind hard alloy, glass, ceramics and other hard to process materials efficiently. The good cutting performance ensures the small grinding force in the grinding process. The thermal conductivity is very good, which is conducive to the evacuation of heat, avoiding the phenomenon of workpiece burn, crack and falling off, and greatly improves the quality of workpiece surface processing