Strong R & D team:Existing doctoral and graduate 12 people, according to technical superiority boreway technology in the field of new materials as well as a solid scientific research technology center in Quanzhou City, we are committed to the development of high-end professional superhard tools. Strong technical strength to excellent quality assurance and laid a solid foundation.

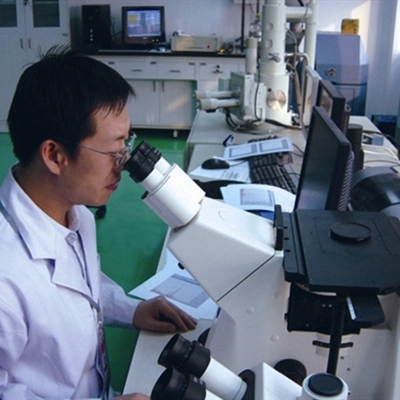

Professional production and testing equipment:The company has the world's most advanced production equipment, diamond tools, head cold, hot, laser welding, laser cutting, tension control, pull teeth and other body strength test equipment from Germany, Japan, South Korea imported semi-automatic equipment. After rigorous training of qualified operating personnel certificates.

A sound quality management system:China the same industry first passed ISO9001 quality management system certification, OSA certification Chinese member. Advanced production technology and processes, 20 processes and standards, quality control points to focus on monitoring. Improve the quality inspection system, the main raw materials, semi-finished products, finished product testing and performance testing project is complete, the key will not compromise the quality characteristics of the release.

Rapid response mechanism:We respect the views and concerns of each customer's quality, based on the pursuit of perfect quality of the production concept, customer feedback information through the standard channels and action plans to be effectively addressed quickly.

Continuous improvement, customer satisfaction for the purpose :To "adhere to continuous improvement, the pursuit of perfect quality and meet customer demand" for quality, the company has always been depending on the quality of life, continuous improvement and improve the quality management system, with excellent products and quality service, the constant pursuit of perfection and innovative spirit, the maximum to meet the needs of new and old customers, and continuously improve customer satisfaction, the company is always pursuit.

Photos description of how to produce saw blade and other tools.