Dry and wet cutting small saw blade generally refers to which saw blade 01?

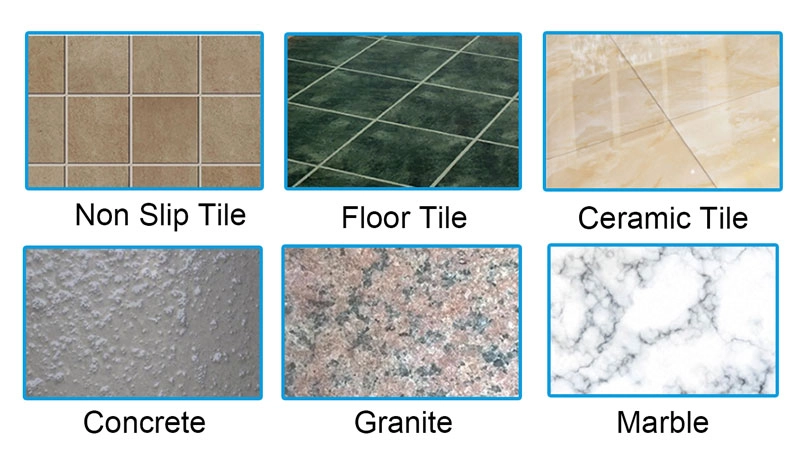

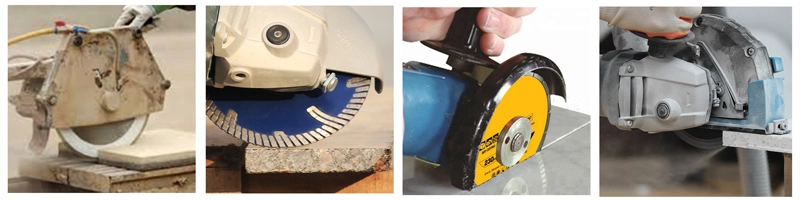

Wet and dry cutting blades are suitable for hand-held devices such as manual, pneumatic cutting machines, angle grinders, etc., professionally dry and wet cutting all kinds of ceramic tiles, glazed tiles, whole bricks, ceramics, marble, microcrystalline stone and other building materials. Because the size of the saw blade is small and medium, it is easy to use, stable cutting without deformation, and flexible usage. It is one of the commonly used diamond cutting series

Wet and dry cutting blades are distinguished according to tooth shape:

2. Continuous tooth saw blade

3. Oblique corrugated saw blade

4. U-shaped saw blade

5. Corrugated saw blade

6. Fine tooth corrugated continuous tooth saw blade

7. Wide tooth corrugated continuous tooth saw blade

8. Saw blade with flange for cutting and grinding

9. Helical corrugated turbine blade

10. Continuous corrugated saw blade

12. Continuous tooth raindrop type

13. Triangle bevel protection blade and other saw blades

Only what you need, we will work out your favorite products for you according to your requirements.

advantage:

1. High sharpness, easy cutting feel, dry cutting without burning chips, good stone versatility, high cost performance!

2. The knife is fast, and the film is not changed for a long time; the cutting is stable, and the head is not dropped.

3. Easy-to-handle key slot design reduces cutting heat expansion resulting in saw blade deformation

4. The substrate is made of 65 manganese steel, which has heat resistance, low temperature resistance and good toughness

5. High tensile strength, impact resistance and high bay strength, not easy to break and deform, and high safety.

6. The manufacturers ship directly, various specifications are flexibly customized, and the quality is reliable and the price is affordable.

Use:

1. Used for cutting non-metallic hard materials such as dry-cut granite, bluestone and other high-hardness stone brick walls and suspicions;

2. Used for stone steel hanging project, wall slotting.

3. Installed on small cutting machines, hand-held cutting machines and angle grinders.

Precautions:

1. The rotation direction of the saw blade must be correct;

2. The cutting machine used must have safety protection when the saw blade is installed, be sure to tighten the fastening nut;

3. The operator must wear protective equipment. Please do not apply pressure to the cutting machine or the curve cutting blade becomes blunt.

4. When dry cutting, please do not cut continuously for a long time, so as not to affect the service life and cutting effect of the saw blade.

5. Water should be added when using wet slices. Please do not cut the curve, please use a special cutting piece for the arc.

6. It is forbidden to use cutting discs for polishing operations, please use professional polishing discs for polishing.

7. If the saw blade is not used for cutting operations in accordance with the relevant requirements, a serious injury may occur.