What is diamond tool bond?

Bond diamond tools for diamond tools are more and more widely used, and the performance requirements of the matrix are different. In order to meet the different performance requirements of the bond

The following three kinds of matrix have been developed for diamond tools:

1. Metal matrix series,

2. Nonmetal matrix series,

3. The series of modified matrix between the two.

Metal bond:

(1) Copper matrix. It is mainly made of pure copper or 663 bronze with soft carcass. It is suitable for cutting jade and other materials.

(2) Iron based carcass. Including pure iron-based or cast iron-based matrix.

The pure iron matrix has a large applicable surface, which is mainly used for drill,saw blade, grinding segment and other tools;

Cast iron matrix is mainly used for manufacturing grinding wheel or grinding wheel. It is characterized by rich materials, low price and unique performance.

(3) Cobalt matrix. It is mainly used to cut large and small cutting saw blades of hard granite stone, and drill bits of special materials such as ceramics, ferrite, etc.

The advantages of this kind of carcass are good comprehensive performance, good bonding performance to diamond, especially strong cutting stress. But manufacturing costs are high.

(4) Nickel matrix. The mechanical properties of the matrix, especially the high toughness, are between iron and cobalt. It is suitable for making various diamond tools.

(5) Tungsten matrix. Tungsten matrix consists of matrix with tungsten, WC or W2C as the main component.

Because the matrix contains a lot of tungsten, WC and W2C, the matrix has high hardness,strong wear resistance and erosion resistance.

It is suitable for manufacturing various drills, reamers, grinding rollers and grinding discs with poor working conditions,etc

There is no strict boundary between these matrices. In most cases, they are a combination of two or more metal or alloy powders. Sometimes in order to obtain some special properties, other metals, alloys and nonmetals are added to the matrix

Nonmetallic matrix nonmetallic matrix includes:

1. Resin bond matrix

2. Ceramic bond matrix

3. Rubber bond matrix

| The role of metal elements in the matrix: |

| 1. The matrix of diamond tools should have certain hardness, strength, impact toughness and wear resistance, so that it can adapt to the rock. |

| 2. At the same time, the matrix should be able to firmly enclose the diamond and make the diamond well exposed to the matrix surface for rock breaking |

| 3. Under working condition, the wear rate of matrix and diamond should be adapted, that is to say, good self sharpening of diamond should be ensured, and matrix should not be abraded too fast to prevent diamond from getting enough support |

| 4. The metal powder that makes up the matrix should be able to erode the diamond, and it should be able to interact with each other in the sintering process without forming |

| 5. As a bonding material, metal or alloy should be able to infiltrate and bond framework material and diamond. |

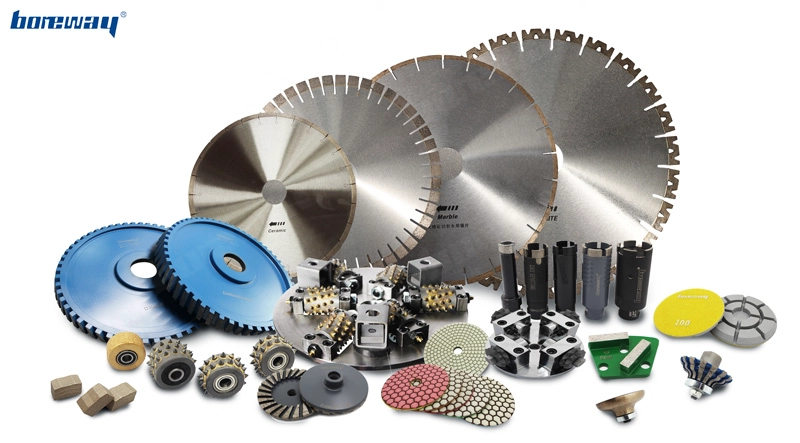

Boreway Machiery Co., Ltd. can produce diamond tools for almost all applications. We can produce and supply the right diamond tools for your application.

Rely on us to help you make the most of your diamond cutting and grinding of materials,drill,Milling, we also have accessories to provide tools.

As long as you need, please contact us:

Mobile/WhatsApp/Wechat: (+ 86) 18650679939

E-mail: boreway@boreway.com