what is diamond CNC milling wheel?

Dora Zhang

2021-06-26 17:29:40

CNC Milling Wheel for Countertop Suppliers,Boreway sells high quality new products: CNC milling wheel

We are familiar with and unfamiliar with this product. What is it specifically used for? Let's find out today?

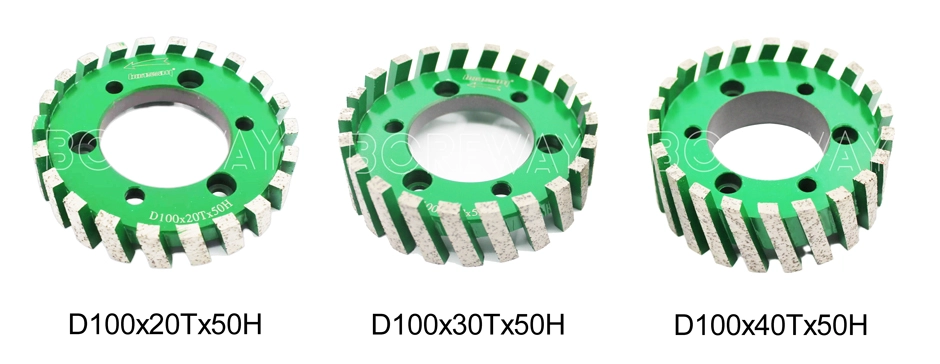

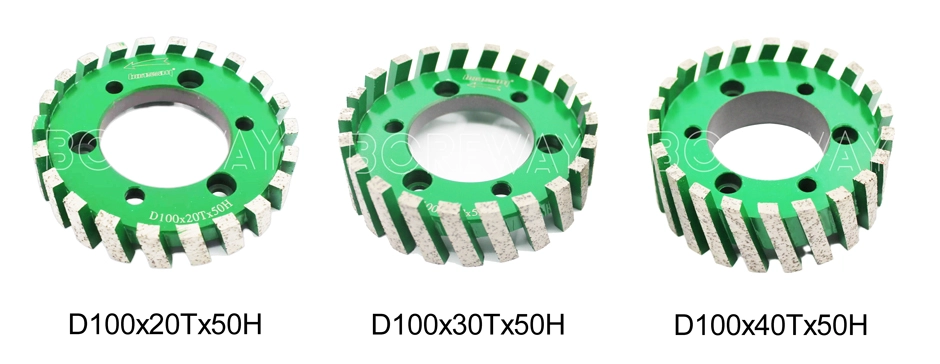

CNC milling wheel is divided into segment milling wheel and continuous milling wheel.

Conventional diameter of segment milling wheel: 50 mm, 86 mm, 90 mm, 100 mm.

Conventional diameter of continuous milling wheel: 50 mm, 90 mm, 100 mm.

Other sizes can be customized.

The milling wheel needs to be used together with the adapter shaft, and a single milling wheel cannot be used by itself. For example: D86 * 30t * 50h diamond heavy duty stubbing wheel with adapter

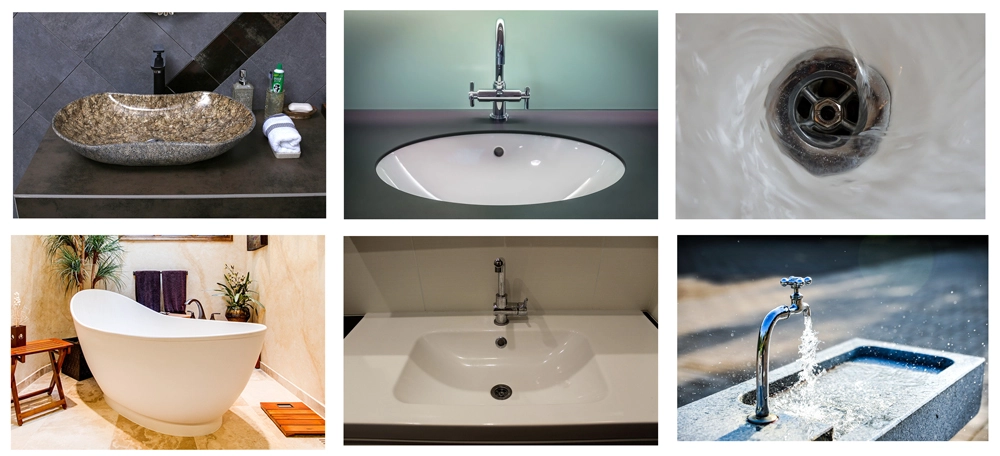

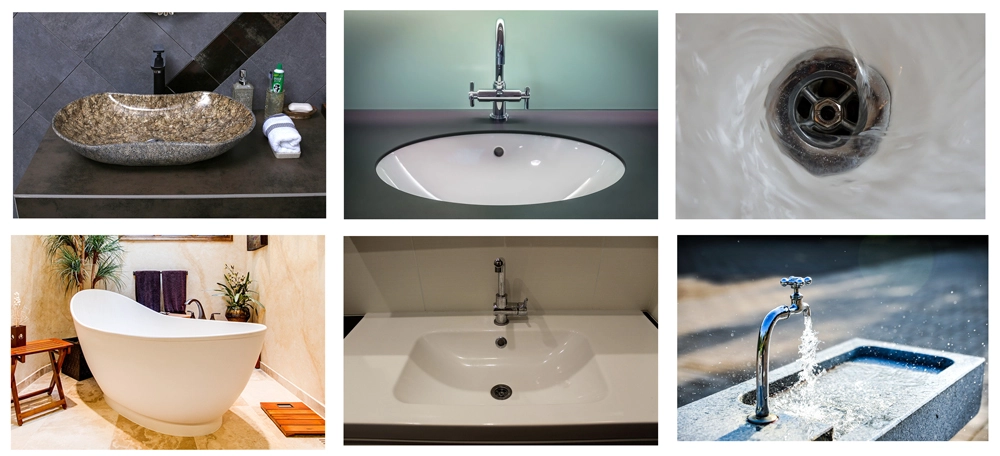

90mm Diamond Stubbing Wheel Suppliers are for grinding and polishing sinkholes on the slab, kitchens etc., which is the most effective way to grind and polish the tight radius.

CNC Milling Wheel for Countertop, are used for very aggressive grinding applications and removal of stock on various materials including granite, concrete, limestone, marble, block, terrazzo and more.

We are familiar with and unfamiliar with this product. What is it specifically used for? Let's find out today?

CNC milling wheel is divided into segment milling wheel and continuous milling wheel.

Conventional diameter of segment milling wheel: 50 mm, 86 mm, 90 mm, 100 mm.

Conventional diameter of continuous milling wheel: 50 mm, 90 mm, 100 mm.

Other sizes can be customized.

The milling wheel needs to be used together with the adapter shaft, and a single milling wheel cannot be used by itself. For example: D86 * 30t * 50h diamond heavy duty stubbing wheel with adapter

90mm Diamond Stubbing Wheel Suppliers are for grinding and polishing sinkholes on the slab, kitchens etc., which is the most effective way to grind and polish the tight radius.

CNC Milling Wheel for Countertop, are used for very aggressive grinding applications and removal of stock on various materials including granite, concrete, limestone, marble, block, terrazzo and more.