How to choose high quality diamond drill bit ?

With the large-scale application of stone, it is inevitable that the lack of Bula stone tools increases. The expansion of stone industry market has gone abroad and challenged the international market.

Want to improve work efficiency, the quality of processing tools to high quality. In order to surprise others in many competitors, it is necessary to choose stone bit carefully.

In the past, when we used non-metallic material tools to process stone, the efficiency was always not high, and it was easy to cause material damage, which formed a certain cost loss.

Now, the hardness of diamond is the highest among all known minerals in nature, reaching Mohs hardness level 10, vacuum brazed diamond core drill bit factory price.

Boreway drill bit, which is famous for its specialty, uses high quality diamond particles as its main processing material

The tool head is welded on the base of drill pipe, which has the advantages of high precision, long service life and high efficiency.

In cutting work, boreway bit is not easy to wear and tear, and its service life is more than ten times that of traditional bit.

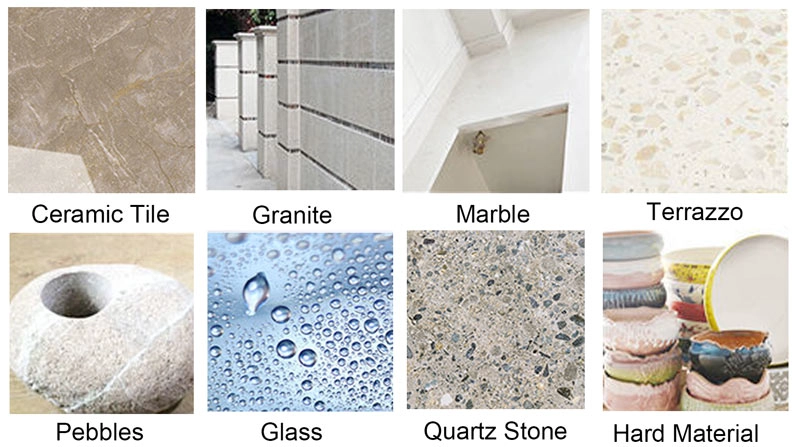

Borewy bit, using high quality diamond particles, does not damage the stone, a wide range of marketing scene.Diamond laser welded core drill bit suppliers.The diamond protrusion uniform, sharp, high drilling efficiency;China concrete core drill bit manufacturer, high quality special bonding matrix, which extends the drilling life and improves the work efficiency; Using high-quality diamonds and high-speed steel pressing and sintering, can withstand high speed drilling.

Ideal for drilling the faucet mounting holes in stone countertops, plumbing lines in showers and vanities