The working principle of diamond tools and the four factors for correct use

The working principle of diamond tools

Under a certain pressure and a certain speed, the material to be processed is ground off by the diamond on the cutter head. In this process, the diamond will also wear, break, and fall off, but at the same time the processed material will also grind away the diamond-encased matrix, exposing the diamond behind to continue working, and continue to complete the processing work.

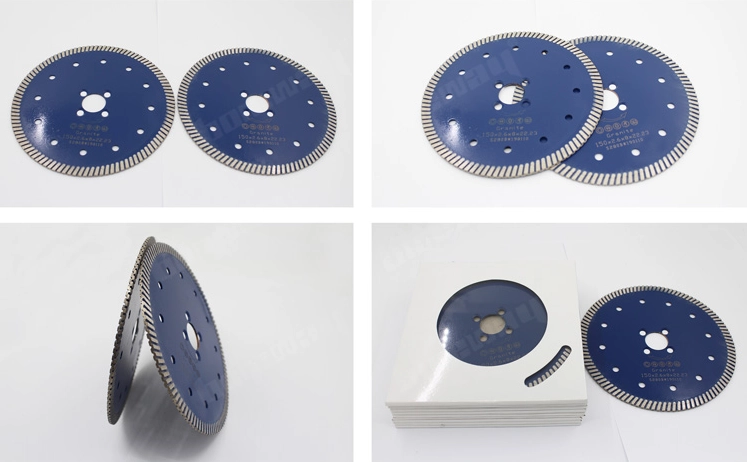

Diamond Grinding Disc For Stone Manufacturer

Correct use of diamond tools

Reasonable selection of diamond tools is of great significance for improving work efficiency and reducing processing costs. Let’s take a diamond saw blade as an example to briefly introduce part of the content: four factors

1. Applicable factors:

According to different processing objects, select general-purpose saw blades, special-purpose saw blades for stone, special-purpose concrete, special-purpose tiles, etc.

Diamond Calibrating Disc For Ceramic

2. Factors for performance matching:

For cutting materials with high hardness and poor abrasiveness, choose saw blades with good sharpness and moderate life to ensure cutting efficiency; for materials with low hardness and high abrasiveness, choose saw blades with long life and moderate sharpness. It is beneficial to reduce the cutting cost.

3. Influencing factors of geometric dimensions:

The size and type of the saw blade should be selected according to the specifications and quality requirements of the cutting material. For example, the diameter of a circular saw blade should generally be three times larger than the workpiece being cut. At the same time, the structure of the saw blade should be selected according to the requirements of machining accuracy, that is, when the sawing surface is required to be smooth or when processing thin and fragile materials, narrow groove or continuous tooth saw blades should be selected. On the contrary, the sawing surface is not high or relatively high. For thick materials, wide groove saw blades can be used.

Diamond Squaring Disc Metal Segment Bond

4. Factors affecting the use of equipment:

For larger equipment power, wear-resistant saw blades can be used to ensure its life, and for lower equipment power, sharp products can be selected to ensure cutting efficiency. For cutting machines with deflection or poor precision, it is best to choose wear-resistant saw blades. For newer cutting machines with good precision, you can choose fast and sharp saw blades.