Why diamond polishing pads are popular used?

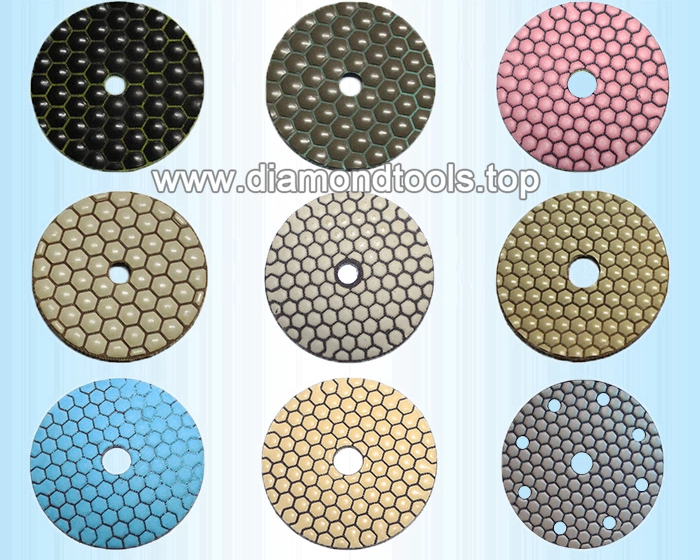

The Right Diamond Polishing Pads for Each Step of the Process

One of the most important factors when preparing to improve the finish of a floor is having the correct type of grade of polishing pads for each part of the process. It is also essential to determine the hardness of the surface being polished. For example, make sure to choose a polishing pad that is specifically designed for marble and granite as opposed to an all-purpose polishing pad.

Cleaning, Buffing and Polishing

In order to achieve the best shine possible, it is necessary to remove all of the dirt and debris that has been ground into the floor. Diamond polishing pads are available in several grits, with the smallest number being the coarsest. For example, if the floor is severely scratched and/or has small chips, start with a 50 grit polishing pad to smooth the surface of the floor, and then increase the grit size for each part of the process.

Diamond polishing pads are designed to be used on standard wet/dry scrubbers, burnishers and high speed floor polishers and in some situations, the same equipment can be used for all steps of process, you simple have to change the type of pad being used.

Maintaining a Glossy Shine

Once the floor has been deep cleaned and polished to perfection it will be easy to keep the shine with routine maintenance. Granite and marble flooring should be cleaned with a mild cleanser designed specifically for natural stone. Floors that undergo heavy traffic, such as those in a bank or school should be cleaned daily and polished with Diamond polishing pads about once a month.

Call us to learn about diamond polishing pads, instructions on use, as well as the other products we have available to help keep the floors of your business looking new.