How should I fit the diamond cup wheel on the machine?

How should I protect myself?

- Eye protection

- Ear protection (ear sets)

- Hand protection (gloves)

- Lung protection (dust mask, also called respirator)

-

Never remove the protective machine guard and make sure it is properly adjusted to deflect debris away from you.

-

Ensure that no other person is at risk, especially near the machine while working

How should I fit the diamond cup wheel on the machine?

Follow carefully the instructions given in the machine handbook.

Never fit a diamond dish/cup wheel which is too loose or too tight on the flange.

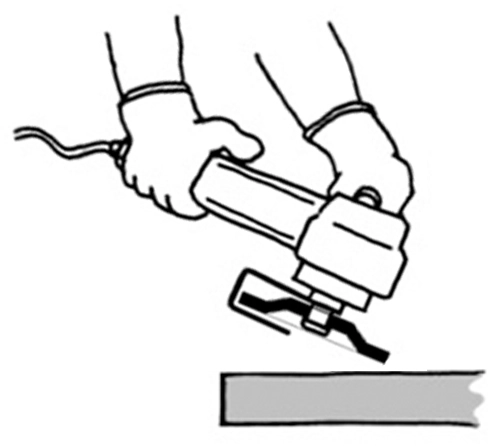

Tighten only with the tool supplied with the angle grinder.

Ensure the wheel is properly gripped to prevent slippage, but do not tighten with excessive force. Never use a hammer.

Keep flanges and screw threads clean and free of burrs and rust.

Replace distorted or damaged flanges before fitting the wheel.

How should I handle the wheel after use?

Before storing the machine or transporting it to another location, always remove the wheel and store it as recommended.

Always carefully examine the wheel for damage or defects, and destroy and discard if damaged.

When disposing of worn out or defective wheels, it is recommended to damage them to prevent someone from removing them from waste and re-using them.

How can I get proper training?

It is a legal requirement for all employees involved in the use of abrasive wheels to be properly trained and also re-trained on a regular basis.

They should consult their employer if they have not received this training.

The wheel manufacturer or supplier can advise you on suitable accredited training providers.