What is the purpose of the electroplating drill bit and what is the purpose of electroplating?

Dora Zhang

www.boreway.com

2020-12-12 17:32:50

The purpose of drill bit plating

The matrix metal is strengthened by alloying methods such as refining the metal grains of the drill bit matrix, compacting the structure, and infiltrating the matrix metal with dissimilar metal atoms to cause various forms of lattice distortion, which will cause the plating or the matrix metal The increase in resistance to movement of grain dislocations leads to an increase in the resistance to deformation of metal materials, and vice versa.

In addition to electroplating drill bits, we also have CNC Diamond Drill Bit Sets For Drilling Stone and crown drill bits , Stone drill bits, ceramic drill bits, tile drill bits, Turbo segment vacuum brazed drill and other high-quality drill bits.

Electroplating method can be divided into epitaxial growth method and conventional method.

Electroplated diamond bits, diamond bits, geological exploration bits, engineering foundation bits.

Electroplated diamond drill bit is a drill bit made by using the principle of electroplating to make the deposited metal (alloy) wrap the diamond particles on the steel body of the drill bit to form a strong and wear-resistant working layer (carcass).

The matrix metal is strengthened by alloying methods such as refining the metal grains of the drill bit matrix, compacting the structure, and infiltrating the matrix metal with dissimilar metal atoms to cause various forms of lattice distortion, which will cause the plating or the matrix metal The increase in resistance to movement of grain dislocations leads to an increase in the resistance to deformation of metal materials, and vice versa.

In addition to electroplating drill bits, we also have CNC Diamond Drill Bit Sets For Drilling Stone and crown drill bits , Stone drill bits, ceramic drill bits, tile drill bits, Turbo segment vacuum brazed drill and other high-quality drill bits.

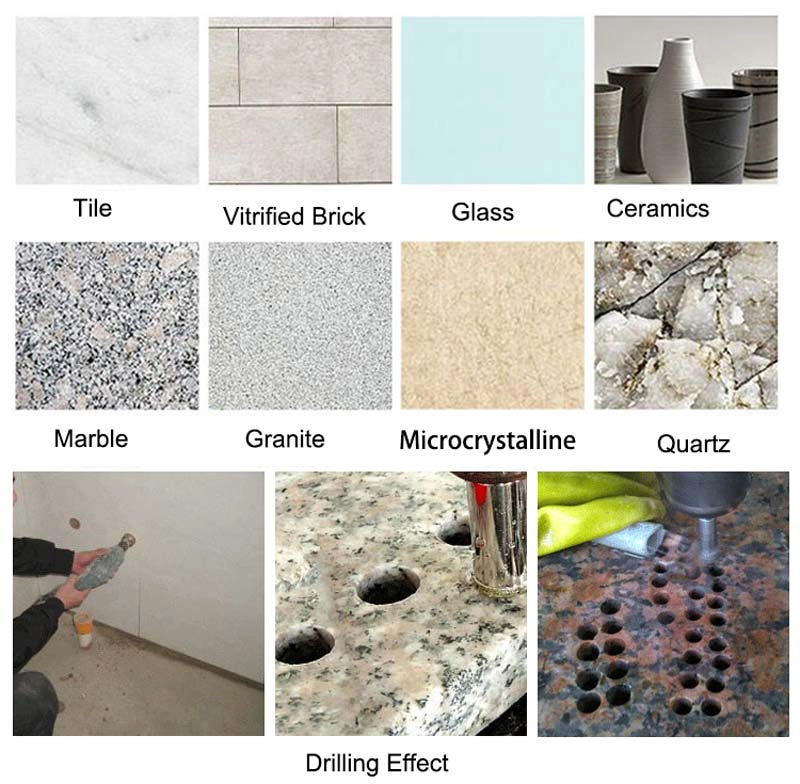

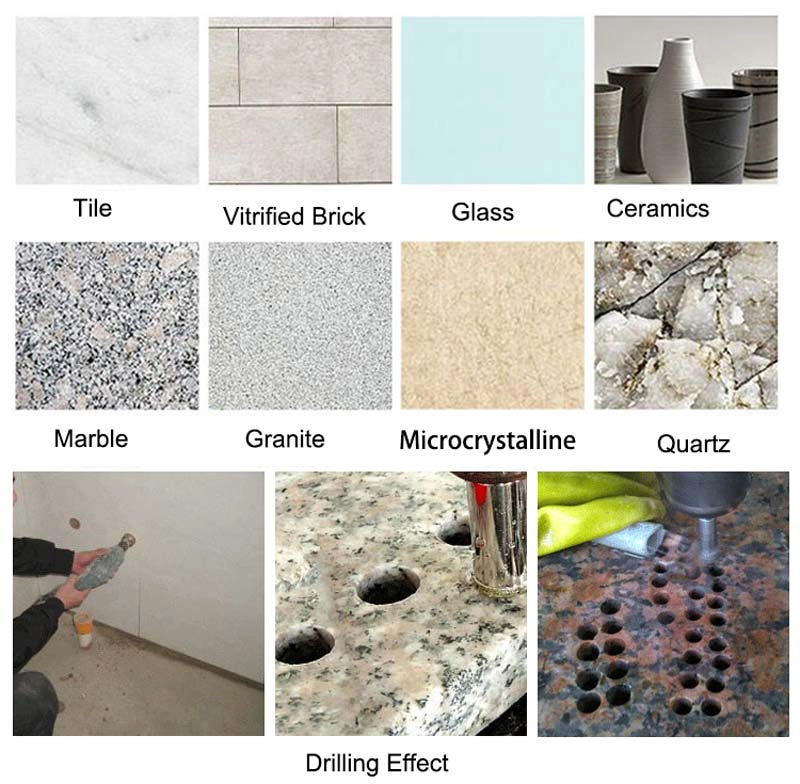

Classified by diamonds used Natural diamond engineering drills use high-quality natural diamonds as cutting materials and are mostly used in building materials, construction, and stone decoration industries. Electroplating drill bits for glass

Synthetic diamond engineering drills use high-quality synthetic diamond single crystals as cutting materials, and are mostly used in optics and chemical industries.

The electroplating method is similar to the manufacturing process of electroplated drill bits.

Synthetic diamond engineering drills use high-quality synthetic diamond single crystals as cutting materials, and are mostly used in optics and chemical industries.

The electroplating method is similar to the manufacturing process of electroplated drill bits.

Electroplating method can be divided into epitaxial growth method and conventional method.

Electroplated diamond bits, diamond bits, geological exploration bits, engineering foundation bits.

How to choose a plating drill bit? The correct choice of cutting speed, cutting amount, and cutting depth are important factors to improve production efficiency.

Electroplated diamond drill bit is a drill bit made by using the principle of electroplating to make the deposited metal (alloy) wrap the diamond particles on the steel body of the drill bit to form a strong and wear-resistant working layer (carcass).