What are the technical requirements for the balance grinding of diamond saw blades?

Dora Zhang

www.boreway.com

2020-12-08 16:58:11

The methods of weight removal mainly include drilling, milling, grinding, laser weight removal and corrosion weight removal.

Aiming at the characteristics of large diameter, thin thickness, and deep sink of the diamond saw blade substrate in this article, the grinding method is selected.

Selection of Balance Grinding Position of Diamond Saw Blade

For the static balance correction of a thin disc rotor with a diameter-to-thickness ratio D/b much greater than 5, it only needs to be performed on a single plane perpendicular to the axis, and this plane is the correction plane. In this study, the diamond saw blade can be regarded as being in a plane, which is used as the correction plane.

Aiming at the characteristics of large diameter, thin thickness, and deep sink of the diamond saw blade substrate in this article, the grinding method is selected.

Selection of Balance Grinding Position of Diamond Saw Blade

For the static balance correction of a thin disc rotor with a diameter-to-thickness ratio D/b much greater than 5, it only needs to be performed on a single plane perpendicular to the axis, and this plane is the correction plane. In this study, the diamond saw blade can be regarded as being in a plane, which is used as the correction plane.

According to the calculation method of static balance, the correction point can also be expressed in size and angular position. In the measurement and correction of the unbalance, the unbalance is generally expressed in the form of m at the position θ, which indicates the magnitude and angular position of the unbalance.

The unbalanced vector is the product of the unbalanced mass and the vector radius.

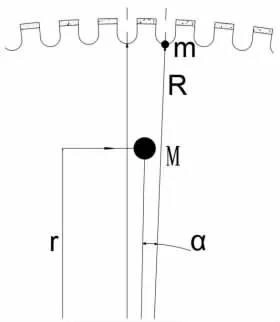

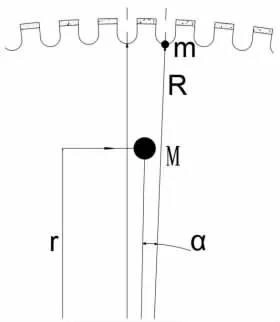

The grooves on the diamond saw blade are generally evenly distributed, and the angle between every two grooves on the saw blade is generally the same. The radius of the unbalanced mass M is r, and the angle α between the centerline of the unbalanced mass and the centerline of the nearest tank can be obtained by the static balance calculation method

To convert the unbalanced mass M to the mass m at the radius R of the sink, it is only necessary to balance at the symmetry of m, as shown in Figure 2.

Figure 2 Unbalanced mass position

According to the calculation requirements of the static balance of the rigid rotor, the unbalanced mass on the rotor can be converted into the removal mass at the symmetry point, or it can be decomposed into components at different points.

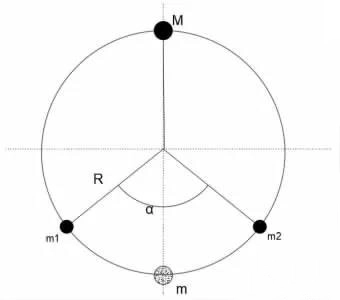

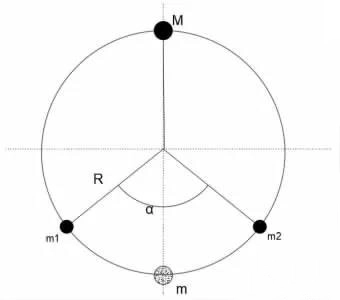

If the correction amount m of the unbalanced mass M is decomposed into two symmetrical components m1 and m2, the angle between them is α, as shown in Figure 3. The unbalance produced by M is U, and the equivalent components m1 and m2 are:

Figure 3 Schematic diagram of equivalent components of unbalanced mass

Article excerpt: Research on the strategy of grinding the unbalanced mass of diamond saw blade substrate

The unbalanced vector is the product of the unbalanced mass and the vector radius.

Therefore, the correction radius should be selected as large as possible within the allowable radius during static balancing to reduce the unbalanced amount of grinding and reduce the actual workload in the correction work. In this case, considering the structure of the diamond saw blade base, all the grinding positions are selected at the bottom of the base sink.

The grooves on the diamond saw blade are generally evenly distributed, and the angle between every two grooves on the saw blade is generally the same. The radius of the unbalanced mass M is r, and the angle α between the centerline of the unbalanced mass and the centerline of the nearest tank can be obtained by the static balance calculation method

To convert the unbalanced mass M to the mass m at the radius R of the sink, it is only necessary to balance at the symmetry of m, as shown in Figure 2.

Figure 2 Unbalanced mass position

According to the calculation requirements of the static balance of the rigid rotor, the unbalanced mass on the rotor can be converted into the removal mass at the symmetry point, or it can be decomposed into components at different points.

If the correction amount m of the unbalanced mass M is decomposed into two symmetrical components m1 and m2, the angle between them is α, as shown in Figure 3. The unbalance produced by M is U, and the equivalent components m1 and m2 are:

Figure 3 Schematic diagram of equivalent components of unbalanced mass

Article excerpt: Research on the strategy of grinding the unbalanced mass of diamond saw blade substrate