Precautions for diamond wire saw cutting

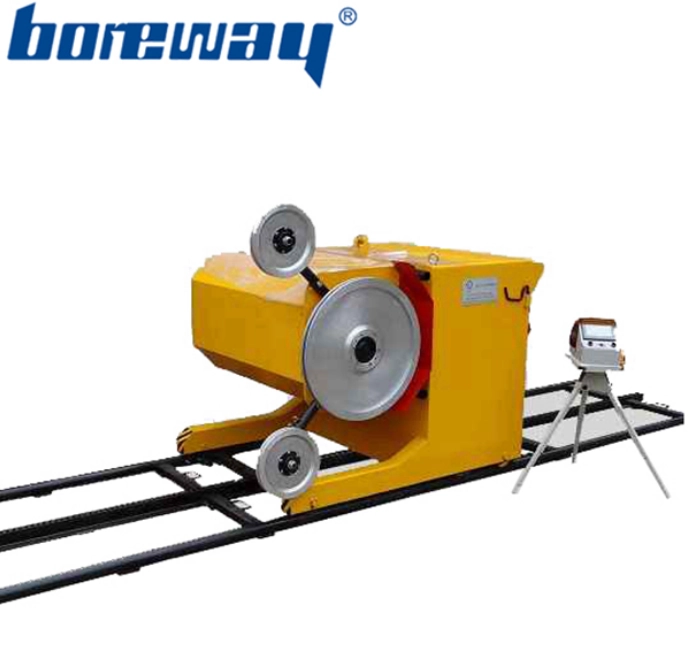

Electric Wire Saw

BOREWAY Diamond Wire Saw Machine in China is a cutting and dismantling tool for mines, blocks, curved slabs, large slabs of stone, thick concrete, irregular concrete steel bars, bridges and roads. So what should I pay attention to when using an electric concrete wire saw to cut?

1. The connection and safety protection technical measures of the relevant operating system of the electric wire saw

According to the site conditions, the connection of water, electricity, concrete wire saw cutting machinery and other related pipelines should be correctly standardized and relatively concentrated, and the wiring placement should strictly follow the safety operation regulations to prevent multiple electric wire saw machines, people, and auxiliary equipment , The materials are randomly placed and placed, causing potential accidents. During the diamond beaded rope cutting process, the front of the diamond rope movement direction must be protected by a safety fence, and safety signs should be set in a certain area to remind pedestrians not to enter the construction work area of the concrete wire saw cutting machine.

2. Diamond beaded wire saw cutting

Start the electric small motor of the electric wire saw machine, adjust the lifting tension of the driving wheel of the concrete wire saw cutting machine through the control panel, ensure that the diamond rope is properly tightened, and supply circulating cooling water, and then start the electric motor of the large motor of the concrete wire saw machine to drive the concrete rope The driving wheel of the sawing machine drives the diamond rope to rotate and cut. During the cutting process of the reinforced concrete cutting machine wire saw, it is necessary to closely observe the stability of the electric wire saw base, and adjust the deviation of the guide wheel of the diamond wire saw at any time to ensure that the diamond cutting rope is in the same plane.(Diamond Wire Saw Beads Wholesales)

3. Selection of parameters of electric wire saw cutting machine

During the cutting process of reinforced concrete, the cutting parameters are adjusted by operating the control panel to ensure that the linear speed of the diamond rope is about 20m/s. On the other hand, sufficient flushing fluid should be ensured during the cutting process of the electric wire saw to ensure the cooling of the diamond rope. And take away the grinding dust, so that the diamond wire saw cutting operation can achieve stable speed, stable parameters and stable equipment.

However, with the rapid economic development, some early elevated roads now seem to have become factors restricting urban development. When rebuilding these elevated structures, it is inevitable to cut and remove some of them, while ensuring that the available components are not affected and can be reused normally.

The diamond wire saw cutting method independently developed and produced by BOREWAY Concrete Wire Saw Machine Supplier China is safe, efficient and environmentally friendly, but the traditional demolition construction can't help it. The BOREWAY electric wire saw effectively solved this problem for us.

Using a diamond wire saw to cut and remove concrete can make the removal of reinforced concrete easier, safer and more effective. BOREWAY electric wire saw cutting reduces labor intensity, safe and reliable operation, strong power, sharp and flat cutting, and improves cutting and dismantling capabilities and engineering efficiency. It is an advanced reinforced concrete cutting and dismantling equipment used for cutting and dismantling construction projects.

Since diamond wire saw cutting is straight cutting, the electric wire saw can make the construction section more tidy and double the working speed, thereby shortening the construction period, further reducing labor costs, improving work efficiency, expanding the scale of construction projects, and greatly Reduce the loss and cost of construction equipment. At present, diamond wire saw cutting is the leading advanced cutting construction equipment widely used in the construction of building renovation projects.