What are the characteristics of high quality diamond calibration wheels?

Diamond calibrating wheels are often suitable for calibrating the thickness of artificial quartz stone plates, and used on medium-hardness plates.

When buying a high-quality fixed-thickness wheel in life, let’s now understand its characteristics.

- Excellent comprehensive cutting performance.

- Fast aggressive stock removal and thickness calibration;

- High processing efficiency and long life for quartz stone calibration;

- Applicable for granites of various hardness classes, multi-purpose.

- Grinds down the rough surfaces and leaves them smooth to the touch.

| Model | Grit | Thickness(mm) | Hole Size(mm) | Diameter(mm) |

| BW-DMW-01 | 24# | 60 | 70 | 190 |

| 36# | 60 | 70 | 190 | |

| 46# | 60 | 70 | 190 | |

| BW-DMW-02 | 36# | 60 | 120 | 200 |

| 46# | 60 | 120 | 200 | |

| 60# | 60 | 120 | 200 |

(Milling Tools Calibration Wheel)is wet use only with sufficient water, Fast & Easy grinding, long life, perfect performance.

The innovative product and tools high quality to make customers process more efficient for different engineered stone.

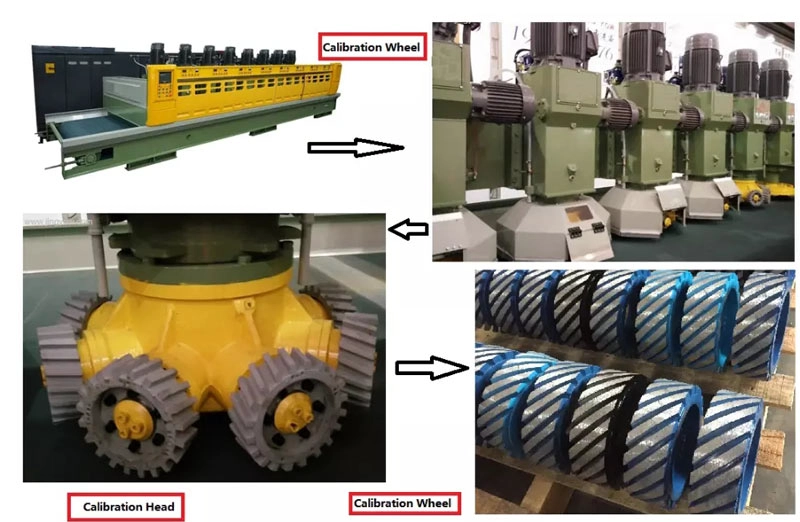

Calibration roller heads: entering calibration, high removal calibration, calibration, pre-finishing, finishing etc wheel as well as the diamond fickert.

It helps eliminate defects formed during moulding.

Currently three designs of segmented calibrating discs are common in use, segmented cylindrical rollers, spiral cylindrical rollers and continuous rim calibrating rollers available as per different machines with same connection size and design.

Diamond calibration roller for profiling machine.