190mm 200mm Diameter Milling Tools Calibration Wheel Diamond Grinding Tools For Artificial Quartz Stone Slab on Sale

- Type:Satellite Head

- Model:BW-DMW-00

- Thickness:60MM

- Hole Size:70MM,120MM

- Diameter:190MM,200MM

- Grit:24#,36#,46#,60#

- Advantage:Long Life, Sharp

- Machine:For Profiling Machine

- Application:Engineered Quartz Granite Marble Stone

190mm 200mm Diameter Milling Tools Calibration Wheel Diamond Grinding Tools For Artificial Quartz Stone Slab on Sale

| Description: |

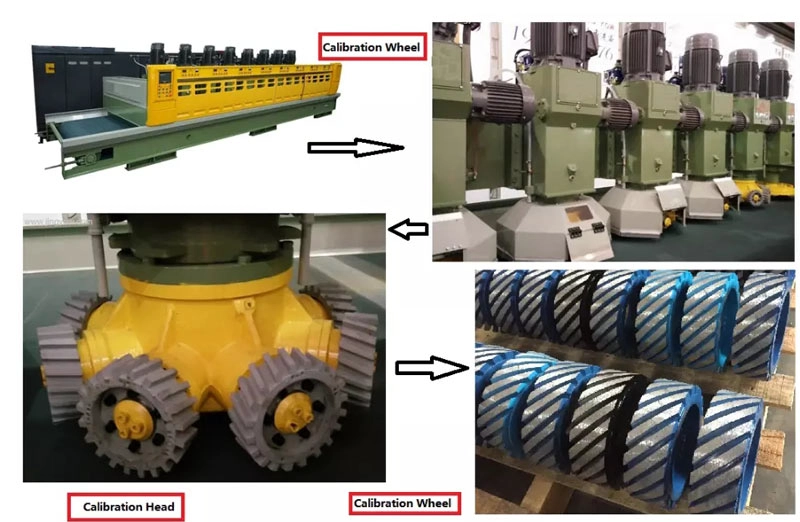

Milling Tools Calibration Wheel is the first step in quartz stone polishing and it is fundamental important in the quartz stone processing and usually the calibration are done on both the top and bottom of the slab. It helps eliminate defects formed during moulding.

Currently three designs of segmented calibrating discs are common in use, segmented cylindrical rollers, spiral cylindrical rollers and continuous rim calibrating rollers available as per different machines with same connection size and design.

| Model | Grit | Thickness(mm) | Hole Size(mm) | Diameter(mm) |

| BW-DMW-01 | 24# | 60 | 70 | 190 |

| 36# | 60 | 70 | 190 | |

| 46# | 60 | 70 | 190 | |

| BW-DMW-02 | 36# | 60 | 120 | 200 |

| 46# | 60 | 120 | 200 | |

| 60# | 60 | 120 | 200 |

Specially designed tools are available for any standard application.

We can customize tools as per your exact needs.

Feature:

1. Excellent comprehensive cutting performance.

2. Fast aggressive stock removal and thickness calibration;

2. Fast aggressive stock removal and thickness calibration;

3. High processing efficiency and long life for quartz stone calibration;

4. Applicable for granites of various hardness classes, multi-purpose.

4. Applicable for granites of various hardness classes, multi-purpose.

5. Grinds down the rough surfaces and leaves them smooth to the touch.

| Product Detail: |

Milling Tools Calibration Wheel

Wet use only with sufficient water, Fast & Easy grinding, long life, perfect performance.

the innovative product and tools high quality to make customers process more efficient for different engineered stone.

calibration roller heads: entering calibration, high removal calibration , calibration , pre-finishing, finishing etc wheel as well as the diamond fickert .

| About Us: |

| Our Service: |

1.Low MOQ: It can meet your trial order need well.

2.OEM Accepted: We can produce according to your sample or drawings.

3.Good Service: We treat our clients as God with high professionalism and passion.

4.Good Quality: We have strict quality control system. Good reputation in the market.

5.Fast Delivery: We have big discount from forwarder.

2.OEM Accepted: We can produce according to your sample or drawings.

3.Good Service: We treat our clients as God with high professionalism and passion.

4.Good Quality: We have strict quality control system. Good reputation in the market.

5.Fast Delivery: We have big discount from forwarder.

| FAQ: |

1.How could we know the quality, if we want to order your products?

Please just test them with a very small order, then you will know the quality. At present,so many people in the world to use Chinese products, because of the high quality and most competitive prices. We are professional manufacturer in supplying diamond tools for more than 8 years. Anyway, confirming our products quality, a small trial order for testing will be necessary.

Please just test them with a very small order, then you will know the quality. At present,so many people in the world to use Chinese products, because of the high quality and most competitive prices. We are professional manufacturer in supplying diamond tools for more than 8 years. Anyway, confirming our products quality, a small trial order for testing will be necessary.

2.Can you offer free samples?

We don’t offer free samples, according to our many years experience, we think people get the samples by paying, they will cherish and appreciate more what they get. But we are willing to give our potential customers a special discount which they are used to do a testing. It is very important to give us feedback, we appreciate it.

3.Does your company accept custom-made?

Surely, we accept it. Including differentcolor, grit etc. We also can mark your ownlogo and brand on the pad. Any new productsyou want us to produce for you, just send us your drawing or sample, we will produce the same one. We will not sell this kind of products to other customers only if we get your permission.

| Contact Us: |

No.605 Huahui Center, Shuitou Town 362342 Quanzhou, Fujian, China

No.605 Huahui Center, Shuitou Town 362342 Quanzhou, Fujian, China TEL: (+86)595-86990206 /

TEL: (+86)595-86990206 /  Fax: (+86)595-86990220

Fax: (+86)595-86990220 Mobile/WhatsApp/Wechat: (+ 86) 18650679939

Mobile/WhatsApp/Wechat: (+ 86) 18650679939  Lyon Chang

Lyon Chang

Fujian Nan’an Boreway Machinery Co., Ltd.

Tel:0086-18650679939

Contact Person:Dora Zhang

PDF Show:PDF