Introduction and classification of BOREWAY diamond saw blades

Diamond saw blade is a cutting tool, which is widely used in the processing of hard and brittle materials such as stone and ceramics. The diamond saw blade is mainly composed of two parts: the base body and the cutter head. The base body is the main supporting part of the bonded cutter head, and the cutter head is the part that cuts during use. The cutter head will be constantly consumed during use, while the base body does not. The reason why the cutter head can cut The role of diamond is because it contains diamond. As the hardest substance at present, diamond friction cuts the processed object in the cutter head, while the diamond particles are wrapped in metal inside the cutter head.BOREWAY Best Price Diamond Saw Blade Manufacturer.

The structure of the diamond saw blade:

1. The matrix is generally 65Mn

2. The cutter head is powder metallurgy. Copper-based, iron-based, nickel-based, cobalt-based, tungsten-based, and aluminum-based powders are formed by hot pressing and sintering with diamond.

BOREWAY diamond saw blade manufacturing process classification

1. Sintered diamond saw blade: divided into cold pressing sintering and hot pressing sintering, pressed and sintered.

2. Welding diamond saw blades: divided into high-frequency welding and laser welding. (High Frequency Welding V cut saw blade)High-frequency welding uses a high-temperature melting medium to weld the cutter head and the substrate together. Laser welding uses a high-temperature laser beam to melt the contact edge of the cutter head and the substrate to form a metallurgical bond. .

3. Electroplated diamond saw blade: attach the blade powder to the substrate by electroplating.

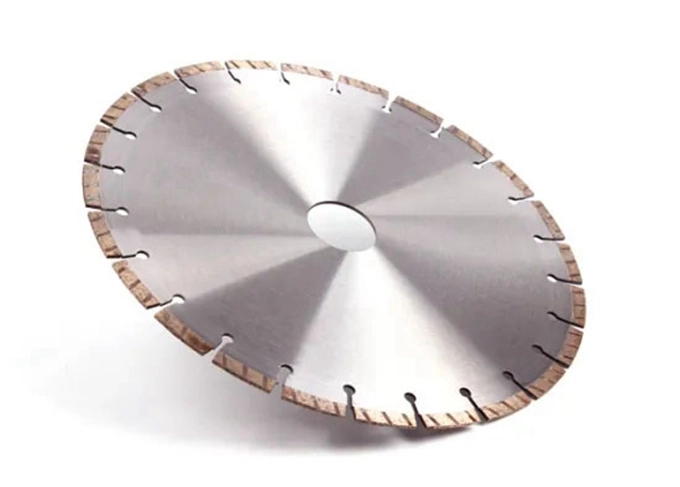

BOREWAY diamond saw blade appearance classification

1. Continuous edge saw blade: continuous serrated diamond saw blade, generally made by sintering method, bronze bond is commonly used as the basic matrix material, water must be added during cutting to ensure the cutting effect, and the type of gap between the cutter head can be cut by laser.

2. Knife-head saw blade: the saw teeth are broken, the cutting speed is fast, and it is suitable for dry and wet cutting methods.

3. Diamond Turbo Wave Saw Blade: Combining the advantages of the previous 1 and 2, the saw teeth continuously present a uniform turbulent convex and concave, which improves the cutting speed and increases the service life.