How to transform epoxy ground

Boreway Machinery offers you a complete range of efficient solutions:

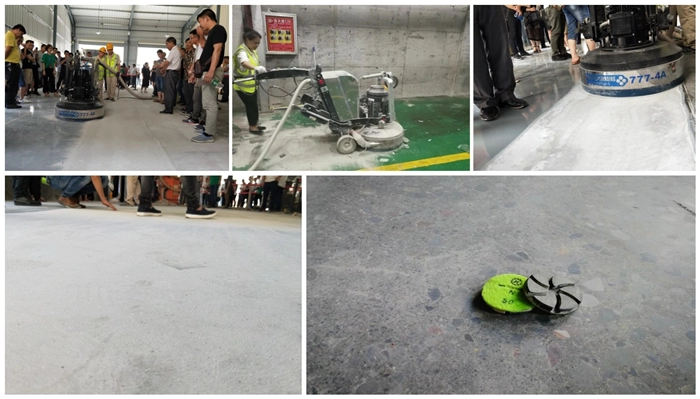

Project address: Epoxy transformation floor of a workshop

Construction process: Use a high-performance grinder to remove the worn epoxy coating on the surface by water grinding. It is recommended to use 120# metal polishing pad. The water grinding method can reduce the coking of epoxy coating during the grinding process by the cooling effect of water.

Floor treatment:

After removing the epoxy coating, there may be some special conditions on the ground. At this time, we have to continue to grind the ground. We need to use 50#, 150#, 300# diamond resin polishing pads for grinding, and also use water grinding. After the grinding is completed, the ground must be thoroughly washed with clean water and the water slurry produced by the grinding is sucked up with a water absorbing machine.

Spray the seal curing agent for the first time and grind:

After grinding, we need to wait for a while, the ground is completely dry and then spray the first time to seal the curing agent. In order to achieve a certain penetration effect, the curing time of the curing agent needs to be about 1 hour. Wait for the curing agent to fully penetrate into the pores of the floor for 4 hours (this time can be extended as appropriate), use the 500# resin grinding disc for the first simple water-grinding, and use a water aspirator to clean the surface water slurry.

Spray the seal curing agent for the second time and finish polishing:

Similarly, we need to wait for the ground to dry thoroughly, and then evenly spray the seal curing agent. If some areas are dried in advance, we can use a scraper to evenly wipe the wet area curing agent.

After the curing agent has fully penetrated into the ground for 6 hours, we use the 1000#, 2000# diamond resin polishing pads to finish the ground polishing (this time requires dry grinding) until the desired gloss effect is achieved.

After polishing:

Note:

The curing process is becoming more and more popular, and the old epoxy modification is one of the major trends. However, whether you are renovating epoxy or curing the ground, the steps of removing the old epoxy and leveling the ground are indispensable, so pay attention to it in the early stage of construction. Do the flatness of the ground.