How to process ultra-thin stone?

Ultra-thin stone as a decorative stone facing material has many advantages such as saving stone resources, saving man-hours, and reducing cost.

1. Preparation before processing. Ultra-thin, stone processing generally uses Diamond gang saw blade suppliers and Fan Edge Cutting Blade And Segment With U Gullet for processing, and these two methods are used for processing At this time, it will produce larger flatness and thickness errors. Therefore, before processing it, it must be polished first. After cutting it into the required specifications, the ultra-thin stone can be cut.

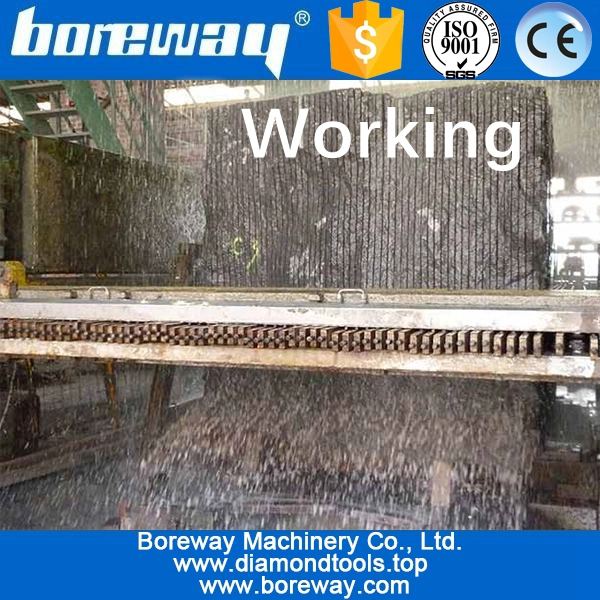

2. Selection of processing equipment. According to different processing requirements, the choice of processing equipment is also different. For example, for ultra-thin processing of marble stone, diamond band saw processing equipment is generally selected, which can cut marble into various types of plates, and the thickness of the cut can be as thin as 2mm.

3. Thickness calculation. After selecting the appropriate processing equipment according to the specifications of the ultra-thin stone, select the appropriate stone cutting blade and measure the width of the cut. Then select the engineering board with a predetermined thickness according to the requirements, and calculate the thickness of the cut board.

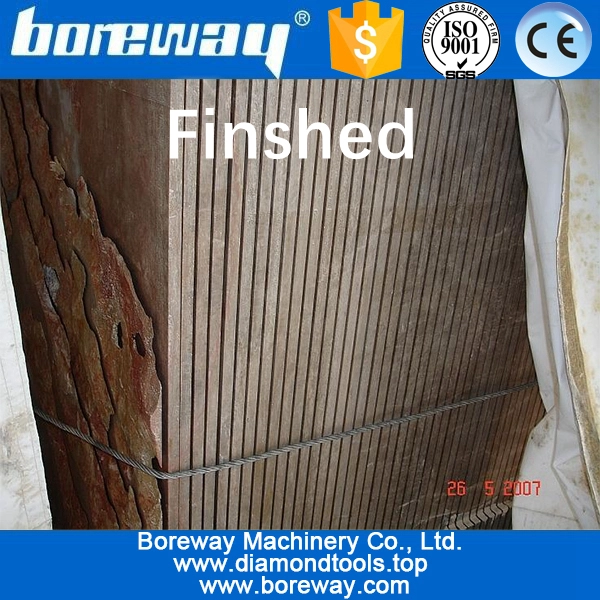

4. After the thickness of the ultra-thin stone is calculated, the ultra-thin stone can be placed in the processing equipment for processing.

(1) The processing of three-dimensional special-shaped stone. The processing of special-shaped stone mainly refers to the processing of stone carvings, door and window covers, vases, etc. The processing methods are mainly chopping, chopping, grinding, shoveling, chiseling, drilling, etc., which can be used manually Processing, mechanical processing is available.

(2) Plane special-shaped stone. For example, kitchen cabinet countertops and table tops are mainly processed by cutting and Shape F20 Diamond Profiling wheels router bit, polishing and other methods.

(3) Surface plate processing. For example, the current processing of cylindrical, arc-shaped plates, etc. are all curved sheet processing, and the main processing method is processing with machinery and equipment.

Advantages of ultra-thin stone

(1) Anti-skinning, anti-falling, anti-coupling, fire-proof, lightning-proof and shockproof;

(2) The system design, from the main material to the supporting materials to the construction process to the specific construction details, is carried out in accordance with the national energy-saving design requirements for external wall buildings. It has more and better thermal insulation functions than traditional energy-saving thermal insulation construction methods.

(3) Long-term decoration

Anti-cracking, waterproofing and pollution prevention have always been the three major problems of exterior wall decoration: the design of the three-proof system of the integrated insulation and decoration system not only guarantees the decorative effect of the first residence, but also makes the energy-saving insulation decorative panel and the building body connected through the technology of the groove. As a whole, coupled with the durability of natural stone, it also guarantees long-term decorative functions and energy-saving insulation performance.

(4) Reduce costs/save resources

Traditional dry hanging of granite stone requires the thickness of the selected granite stone to be about 30mm, while the ultra-thin stone insulation decorative board uses ultra-thin stone as the exterior wall finish. The thickness of the ultra-thin stone is only 8-12mm, and only the thickness of the dry-hanging granite stone It can save and effectively use our country’s granite stone resources and imported precious stones, while reducing the system cost.