How to Judge the Quality of Diamond Segments?

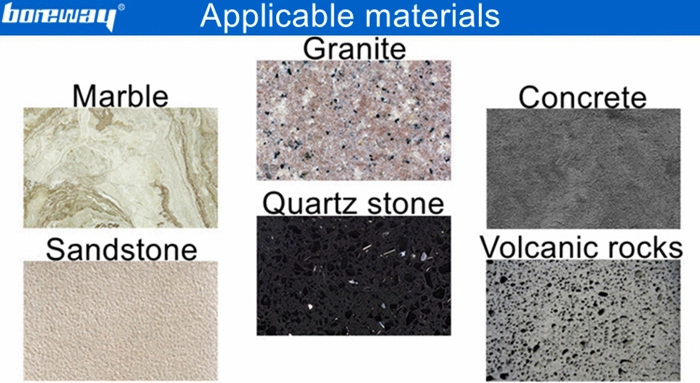

As a widely-used cutting tool, Diamond Segment play a vital role in cutting stone and porcelain.

Good quality diamond segment can assure us of smooth cutting and less malfunction.

So Having a good knowledge of what is good diamond segment is very important.

Below are some parameters for determination of good quality diamond segment.

1) Grit of diamond segment

Generally speaking,for diamond segment,diamond powder grit 30/35~60/80. the harder the stone is, the smaller the grit is, the sharper the diamond segment is.

Besides, for diamond segment of big diameter, since cutting efficiency need to be ensured, bigger grit is suggested, like 30/40,40/50

2) Concentration of the cutting segment.

Concentration refers to the density of diamond powder in the diamond segment. When the diamond segment contain 4.4 carats of diamond powder per cubic centimeters, we determine the diamond segment of concentration 100%; while, when the diamond segment contain 3.3 carats of diamond powder per cubic centimeter, we determine the diamond segment concentration 75%.

The volume concentration indicates the volume of diamond powder in the whole block. When volume of diamond powder hits 1/4 in the whole diamond segment,we judge the volume concentration 100%. Increasing the concentration of diamond segment can help extend its lifespan, because average cutting force for every diamond powder be reduced with the diamond powder concentration increasing.

3) Hardness of the diamond segment.

Generally speaking, the harder the metal bond is, the stronger its anti-wear capability is. Harder metal bond is suggested when it comes to cutting stone of high-abrasiveness; soft bond is suggested when it comes to cutting soft stone; bond of medium hardness is suggested when cutting stone of high abrasiveness and hardness.

4) Effect

Force effect, the granite segment is subjected to axial force and tangential force. Due to these force, the diamond segment go wavy in axial direction and show disc shape in radial direction. Both deformation will result in uneven cutting surface of stone, waste of stone, heavy noise and great vibration of diamond segment, then we will see early damage of diamond segment, short lifespan.

Temperature effect, the influence of temperature on diamond segment mainly reflected in two aspects: first, cause graphitization of diamond powder in the diamond segment; second, cause the premature detachment of diamond powder due to the thermal stress of diamond powder and metal bond. New research shows that the heat generated during the cutting process is mainly transmitted into the diamond segment.

More other informations, welcome to contact with us :) write to boreway05@boreway.net