How to Choose Diamond Cup Wheel?

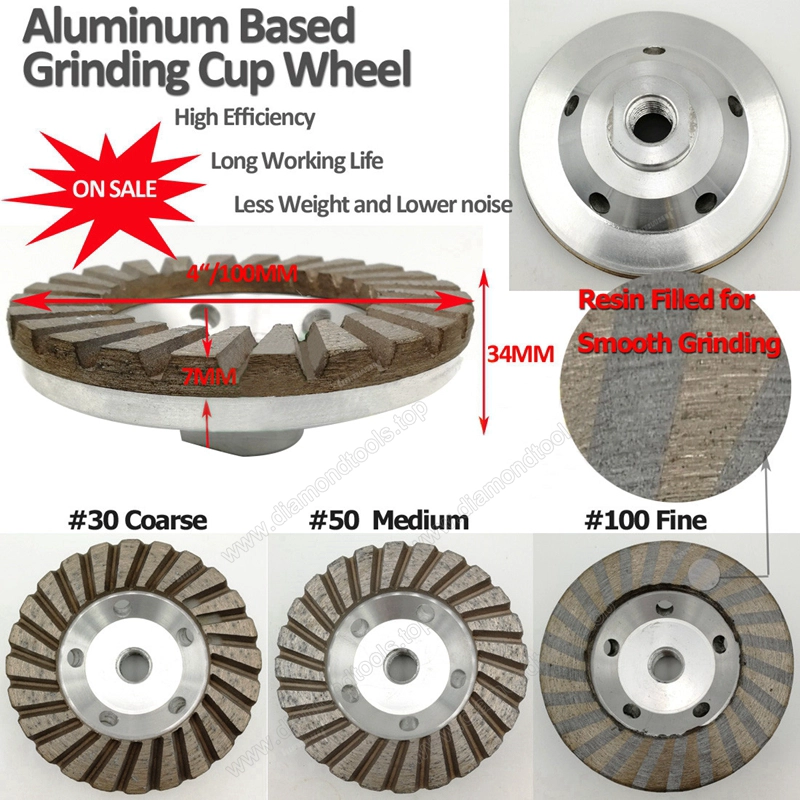

Just like other metal-bonded diamond tools, diamond segments on diamond grinding cup wheels have different bonds, different diamond grits, different diamond quality and different diamond concentrations to fit different uses.

For example, if stone or concrete to be ground is hard, the bond should be softer, and if the material is relatively soft, the bond should be harder.

Diamond cup wheels are used in different grindings. For coarse grinding, the bond should be softer and the diamond quality should be higher, because in this case the diamonds become blunt more easily. Diamond grits should be more coarse, normally from 35 grit to 50 grit, because coarse grinding with coarse grits can improve working efficiency. The diamond concentration should be lower.

For fine grinding (sometimes called "polishing"), the bond should be harder and diamond quality can be lower, as in this case diamonds can last longer and a hard bond can also help achieve precise processing. Diamond grits are normally between 80 grit and 120 grit, depending on grinding requirements. The diamond concentration should be higher.

After being ground, the material can be further polished with resin-bonded diamond polishing pads of different diamond grits.

More details, welcome to contact with us :) Pls send email to boreway05@boreway.net