How about high frequency welding of saw blade?

Dora Zhang

2022-07-29 15:11:15

High frequency welding cutting segment diamond bit can be applied to diamond saw blade and other diamond tools.

Today, learn how to weld the cutting tool head to the saw blade?

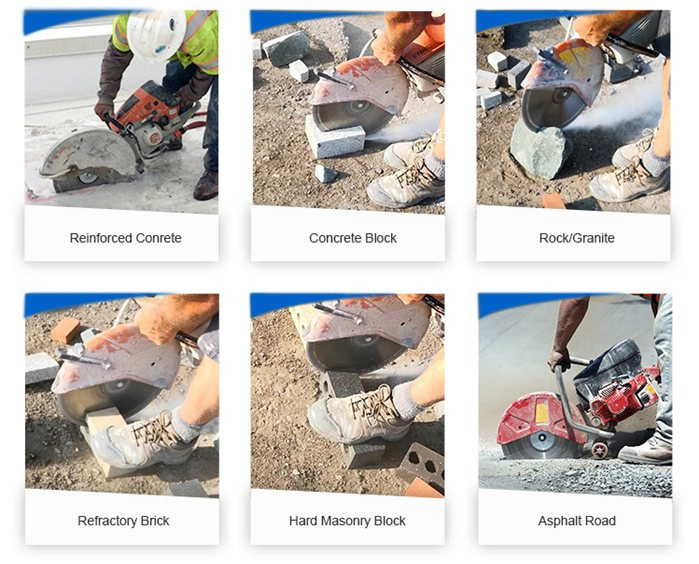

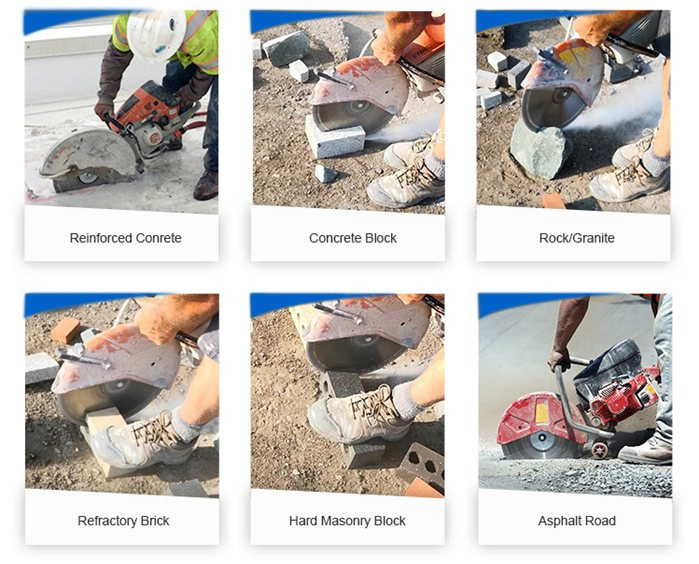

Circular saw blades for concrete, stone, brick, concrete floor and other materials.

There are two common welding methods in the process of diamond saw blade welding, namely, high-frequency welding and laser welding. How many people don't know very well, and what is it?

High frequency welding is a very common way

1. It has strong applicability and can be used for 205mm-3500mm saw blades

2. High frequency welding equipment has a high price ratio and a large audience, which is enough to meet the welding of most saw blades.

3. Save time and personnel, upgrade equipment, and process by means of semi-automatic and automatic welding machines to reduce labor costs.

Diamond circular saw blade for cutting marble service life of cutting single type and specification board can reach more than 3000 square meters.

Today, learn how to weld the cutting tool head to the saw blade?

Circular saw blades for concrete, stone, brick, concrete floor and other materials.

There are two common welding methods in the process of diamond saw blade welding, namely, high-frequency welding and laser welding. How many people don't know very well, and what is it?

High frequency welding is a very common way

1. It has strong applicability and can be used for 205mm-3500mm saw blades

2. High frequency welding equipment has a high price ratio and a large audience, which is enough to meet the welding of most saw blades.

3. Save time and personnel, upgrade equipment, and process by means of semi-automatic and automatic welding machines to reduce labor costs.

Diamond circular saw blade for cutting marble service life of cutting single type and specification board can reach more than 3000 square meters.