How to grind the ground with the floor grinding block?

Applications: suitable for general (concrete,stone) grinding use while mostly they are used for paint, glue, epoxy removal and floor coating, high quality and high efficiency, long lifespan.(China Factory Quick change Concrete Grinding Discs)

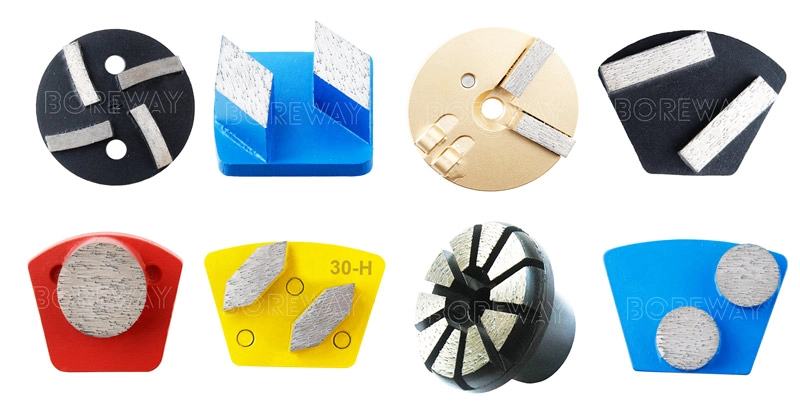

The base of the grinding block has round, trapezoidal, triangular and other shapes. The grinder can not only be installed with grinding blocks, but also with metal grinding discs. There are more specifications of 10 inch. (China PCD Diamond HTC Grinding Shoes Supplier)

The grit sizes of the grinding discs are: 6#, 16/18#, 20/25#, 30/40#, 50/60#, 70/80#, 80/100#, 120/150#, 200#/220# , 325/400#

Floor is a collective term for all kinds of ground, which means that through certain specific tools, materials and corresponding construction techniques, the ground will finally show a certain decorative effect and special functions

After the floor is laid, it is generally necessary to use a floor grinder equipped with a floor grinding block for smoothing and polishing.

The floor grinding block includes a base for connecting with the floor grinder and a cutter head set on the base. The cutter head is an integral block that is directly sintered through a shaping mold according to the required shape. The cutter head is integral with the base.

It is connected as an integral structure by welding. When in use, the floor grinder drives the cutter head on the substrate to achieve grinding. When the floor abrasive block grinds the rough concrete floor, due to the large amount of abrasive debris and strong abrasiveness, the cutter head Severe wear makes the cutter head short in service life, and the whole piece of cutter head is directly welded to the base body.

The welding area is large, and the base body cannot be re-welded. Once the cutter head is worn out, the entire floor grinding block will be scrapped and used for one time.

Resulting in a waste of resources, and the overall disassembly and assembly of the floor grinding block is troublesome and inconvenient to use, which affects the efficiency of the grinding tool.