Do you know the grinding tools for rough grinding of open faced concrete?

The diamond grinding block is installed on the chassis grinding machine. The boreway manufacturer supplies many types of grinding blocks to meet the needs of customers.

1. Floor Polishing Wheel

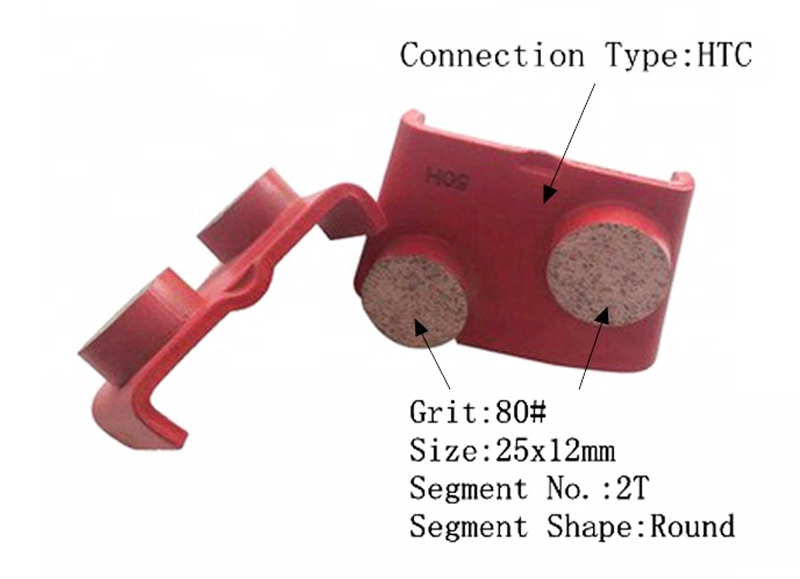

2. HTC Floor Grinding Pad (eg: Double Round Segment HTC Metal Bond Grinding Diamond For Concrete Floor)

3. Lavina Floor Grinding Pad

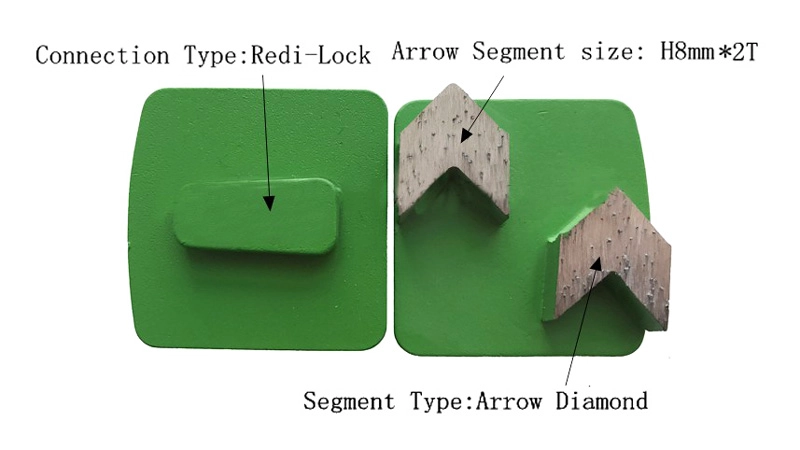

4.Redi-lock Floor Grinding Pad (such as: Redi Lock Concrete Floor Grinding Disc With Single Arrow Diamond

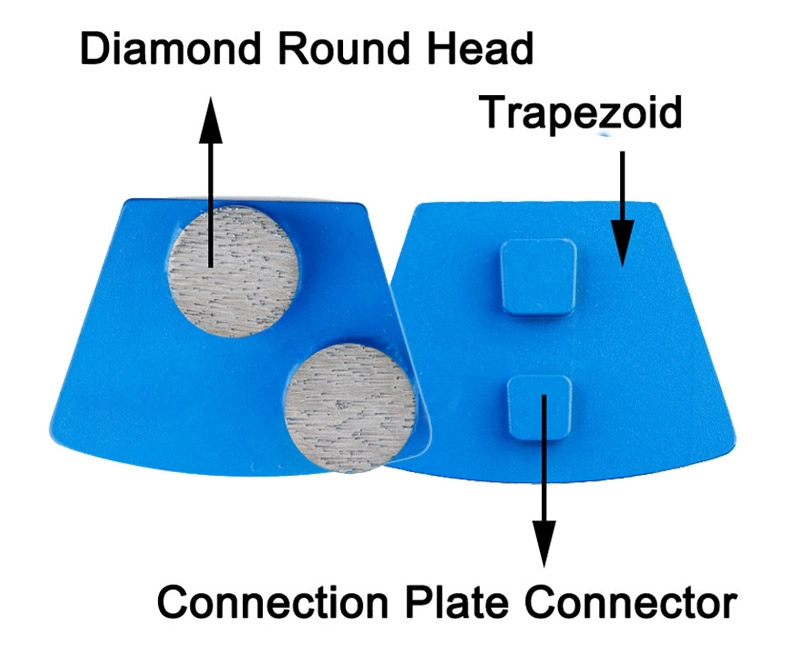

5.Trapezoid Floor Grinding Pad (such as: Two Round Segment Diamond Grinding Disc is used for foundamental processing of all kinds of concrete floor, terrazzo, stone floor leveling, coarse grinding, fine grinding before much more finer polishing steps.)

6.Grinding Head & Grinding Disc

7.Flat-plug diamond grinding blocks

Segment Shapes: Rectangle, Round, Arrow, Oval, Rhombus etc

Suitable for STI machines, HTC machines, Redi-Lock System for Husqvarna Grinding Machine, etc.

Rough grinding and grinding of the "open surface" leveling concrete is the first step in the actual operation of the concrete floor curing (hardening) polishing process, which is very important. If this area is not done well, the uneven surface will not be smoothed after rough grinding.

Here, "open face" means to cut the surface. Of course, this refers to cutting (grinding) the surface of concrete with a coarse diamond abrasive block or abrasive tool with a floor grinding machine. The purpose is to expose the concrete and open the pores so that the sealing curing agent can effectively penetrate and seal.

The "open surface" of rough grinding includes two basic elements-opening pores and exposing sand and rough grinding and leveling.

Diamond Concrete Floor Grinding Plates are the best solution for large areas of thin coating removal, leveling and smoothing high spots in concrete, and work very well for concrete cleaning.

Their segments are designed for aggressive grinding of concrete to make short work of your larger projects .