Do You Know About The Diamond Flap Disc?

Do You Know About The Diamond Flap Disc?

With the rapid development of abrasive industry, there are many kinds of abrasive now, but the more widely used abrasive is the diamond flap disc.

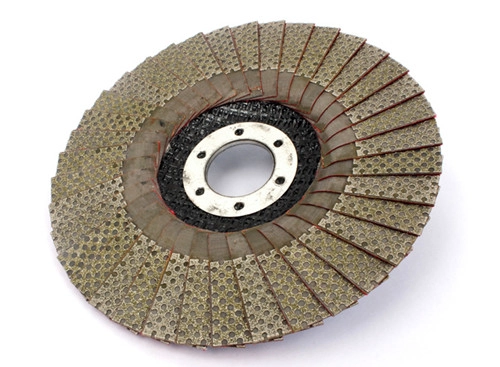

Diamond flap disc is a large variety of coated abrasives conversion products. It is made by pressing the cut Coated Abrasives one by one along the circumference with adhesive on the back cover plate. It is a product needed in industrial production.

It is mainly installed on the hand-held electric tools for grinding and polishing the welds, burrs, chamfers, surface rust removal and surface polishing of all kinds of metal and non-metal parts. Compared with the resin bonded abrasive wheel, the grinding and polishing are completed once.

The diamond flap disc can effectively shortens the operation time, saves the grinding cost, improves the grinding efficiency, has the advantages of high utilization rate of abrasive self sharpening, no damage to the surface by air cooling, easy surface quality control and high cost performance, reduces operator fatigue, increases machine life, etc., and is widely used in various industries or fields of manufacturing industry.

The diamond flap disc can also replace the resin needle wheel. It has high elasticity, good self sharpening, high grinding rate and low noise. It is suitable for the grinding of the welding seam in the box and the burr of stamping parts. It is used for the grinding and polishing of various stainless steel and carbon steel structural parts. The new design makes the basic body completely separated from the sand plate, convenient for manual decoration and very environmental protection.