Boreway Granite Cutting Diamond Segment Using in Block Cutting

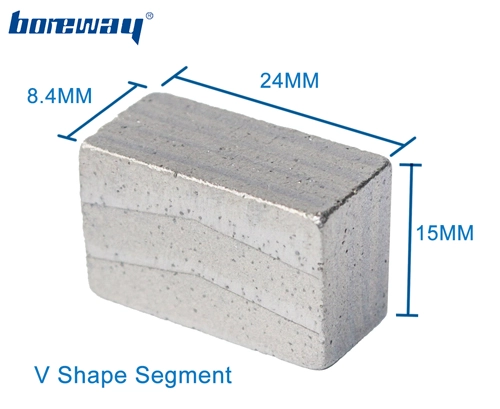

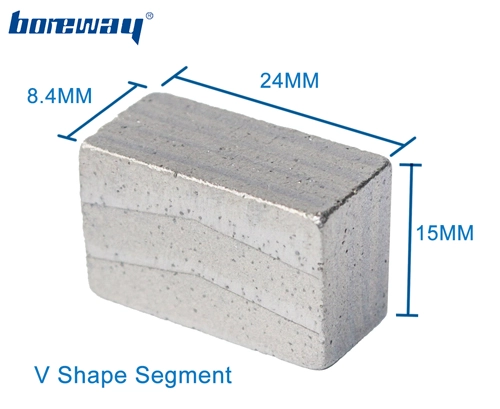

- Shape:V shape

- Segment No.:88pcs

- Brand Name:Boreway

- segment length:24mm

- Segment height:15mm

- Segment Width:8.4mm

- Type:Sandwich,Groove,etc

- Model Number:BW-DSGB-02-06

- Place of Origin:Fujian, China

- Out diameter for saw blade:1350mm

- Manufacturing Arts:Sintered,hot press,cold press

- Machine:for Silver welding by high frequency welding machine.

- Application:Diamond segment for granite marble cutting,stone,etc

Boreway Granite Cutting Diamond Segment Using in Block Cutting

Granite Cutting Diamond Segment Using in Block Cutting

Granite cutting diamond segment using in block cutting Wet use only.

Granite cutting diamond segment using in block cutting for 900-3500mm circular saw blades for block cutting

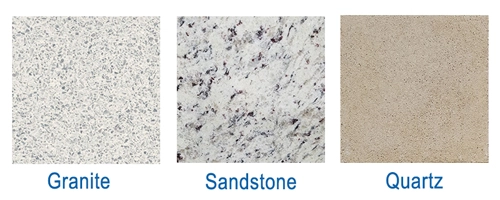

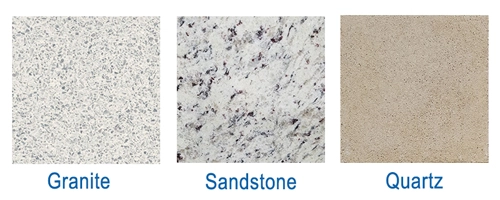

Diamond segment cutting granite, sandstone, various hard stone with quartz.

Granite cutting diamond segment using in block cutting

High frequency silver welded machine is recommended instead of welding by fire.

Don’t weld diamond segment for a long time, just a few minutes, otherwise the diamond inside might be damaged because of the high temperature, which will affect the cutting performance of the granite segment greatly.

No.605 Huahui Center, Shuitou Town 362342 Quanzhou, Fujian, China

No.605 Huahui Center, Shuitou Town 362342 Quanzhou, Fujian, China

TEL: (+86)595-86990206 /

TEL: (+86)595-86990206 /  Fax: (+86)595-86990220

Fax: (+86)595-86990220

Mobile/WhatsApp/Wechat: (+ 86) 18650679939

Mobile/WhatsApp/Wechat: (+ 86) 18650679939

Lyon Chang

Lyon Chang

|

Feature:

|

1. Granite cutting diamond segment using in block cutting are great adaptability,No chipping.

2. Working safe, quiet, and precise, reducing cutting,working time.

3. Different bonds are for different applications,precise segment size.

4. Fast cutting,long life,Stable performance, High grade of diamonds.

2. Working safe, quiet, and precise, reducing cutting,working time.

3. Different bonds are for different applications,precise segment size.

4. Fast cutting,long life,Stable performance, High grade of diamonds.

| Specification: |

The following are normal specifications granite cutting diamond segment using in block cutting:

| Code. | Diameter (mm) |

Length | Width (Taper Type) | Height | Segment No. |

| BW-DSGB-02-06 | 1350mm | 24 | 8.4/7.9/7.4 |

12/15/20 | 88 |

The above specifications is only for reference, other specifications may be available as per customer's demand.

PS:A certain amount of cooling water should be added when cutting the cutter head, and the spray water flow should be large, so that it has a better cooling effect!

In addition, the speed of the combined saw blade is required to be 280-320 rpm, and the trolley can not be transported too fast!

| Product Details: |

Example :

Stone is soft and abrasive therefore we would use a hard bonded blade. Reinforced concrete with river pebble aggregate is hard therefore we would use a soft bonded blade.

Stone is soft and abrasive therefore we would use a hard bonded blade. Reinforced concrete with river pebble aggregate is hard therefore we would use a soft bonded blade.

Hard Bond

Means that the compilation of metals when sintered together forms a segment of approximately 105 to 120 HRB (hardness) and is very resistant to the soft abrasive materials being sawn, thus releasing diamond at the appropriate rate.

Hard bonds typically consist of the following metal powders – cobalt, iron, tungsten carbide and are grey to dark grey in colour.

Means that the compilation of metals when sintered together forms a segment of approximately 105 to 120 HRB (hardness) and is very resistant to the soft abrasive materials being sawn, thus releasing diamond at the appropriate rate.

Hard bonds typically consist of the following metal powders – cobalt, iron, tungsten carbide and are grey to dark grey in colour.

Soft Bond

Means that the compilation of metals when sintered together forms a segment of approximately 90 to 105 HRB (hardness) and allows the segment to wear quicker thus retaining diamond on the cutting surface.

Soft bonds typically consist of the following metal powders - copper, bronze and cobalt, and are generally bronze to light silver in colour.

Means that the compilation of metals when sintered together forms a segment of approximately 90 to 105 HRB (hardness) and allows the segment to wear quicker thus retaining diamond on the cutting surface.

Soft bonds typically consist of the following metal powders - copper, bronze and cobalt, and are generally bronze to light silver in colour.

| Applications: |

Granite cutting diamond segment using in block cutting for 900-3500mm circular saw blades for block cutting

Diamond segment cutting granite, sandstone, various hard stone with quartz.

| Applications machine: |

Granite cutting diamond segment using in block cutting for granite cutting used for single or multi circular saw blade from 900mm to 3500mm, cutting of granite, sandstone, various hard stone with quartz.

The features of the granite cutting diamond segment using in block cutting should match the nature of the material to be cut.

1. If the material is hard, the bond of the diamond segments should be softer.

Because diamonds will become blunt when cutting hard material. Softer bond can be

worn down with the blunt diamonds faster, then make new diamonds beneath be more easily exposed to participate in cutting

Because diamonds will become blunt when cutting hard material. Softer bond can be

worn down with the blunt diamonds faster, then make new diamonds beneath be more easily exposed to participate in cutting

2. If the material is relatively softer, the bond should be harder.

The diamonds can last longer in this care. The harder bond wears slower, so that it can hold the diamonds also longer. This can make better use of the diamonds and prolong the diamond tool's service life.

| Applications machine: |

High frequency silver welded machine is recommended instead of welding by fire.

Don’t weld diamond segment for a long time, just a few minutes, otherwise the diamond inside might be damaged because of the high temperature, which will affect the cutting performance of the granite segment greatly.

| About us: |

| Our service: |

1. Low order quantity: It can meet the test order you need.

2. Fast delivery: We get great discounts from freight forwarders.

3. OEM Acceptable: We can produce according to your samples or drawings.

4. Good quality: We have a strict quality control system. Has a good reputation in the market.

5. Good service: We regard our customers as God with a high degree of professionalism and enthusiasm.

2. Fast delivery: We get great discounts from freight forwarders.

3. OEM Acceptable: We can produce according to your samples or drawings.

4. Good quality: We have a strict quality control system. Has a good reputation in the market.

5. Good service: We regard our customers as God with a high degree of professionalism and enthusiasm.

| FAQ: |

1. If we want to order your product, how do we know your quality?

You can test with a small order, and then you will know the quality. Nowadays, many people in the world use Chinese products because of their high quality and high cost performance. We are a professional diamond tool manufacturer with more than 8 years of manufacturing experience.

2. Can you provide samples for free?

We do not provide free samples. Based on years of experience, we believe that customers will want them because of their reliable quality. By purchasing samples, we will cherish and appreciate them and make them get more. We are ready to offer our potential customers a special discount on samples. It's very important that you give us feedback, and we will appreciate it.

3. Does your company accept customization?

Of course, we accept customization. Including different colors, cutting objects, etc. We can also tag your own label and company brand. If you want us to make any new products for you, just send your products to us. Whether it's drawings or samples, we have the ability to produce the same products. We will not sell these products to others, only customers can get permission.

You can test with a small order, and then you will know the quality. Nowadays, many people in the world use Chinese products because of their high quality and high cost performance. We are a professional diamond tool manufacturer with more than 8 years of manufacturing experience.

2. Can you provide samples for free?

We do not provide free samples. Based on years of experience, we believe that customers will want them because of their reliable quality. By purchasing samples, we will cherish and appreciate them and make them get more. We are ready to offer our potential customers a special discount on samples. It's very important that you give us feedback, and we will appreciate it.

3. Does your company accept customization?

Of course, we accept customization. Including different colors, cutting objects, etc. We can also tag your own label and company brand. If you want us to make any new products for you, just send your products to us. Whether it's drawings or samples, we have the ability to produce the same products. We will not sell these products to others, only customers can get permission.

| Please note: |

Please use high frequency Silver Welded machine instead of Fire to make the brazing, the welding time is only a few seconds, otherwise the diamond inside the segments will probably be damaged by the high temperature, then the cutting performance will be Reduced!

| Contact us: |

No.605 Huahui Center, Shuitou Town 362342 Quanzhou, Fujian, China

No.605 Huahui Center, Shuitou Town 362342 Quanzhou, Fujian, China TEL: (+86)595-86990206 /

TEL: (+86)595-86990206 /  Fax: (+86)595-86990220

Fax: (+86)595-86990220 Mobile/WhatsApp/Wechat: (+ 86) 18650679939

Mobile/WhatsApp/Wechat: (+ 86) 18650679939  Lyon Chang

Lyon Chang

Fujian Nan’an Boreway Machinery Co., Ltd.

Tel:0086-18650679939

Contact Person:Dora Zhang

PDF Show:PDF