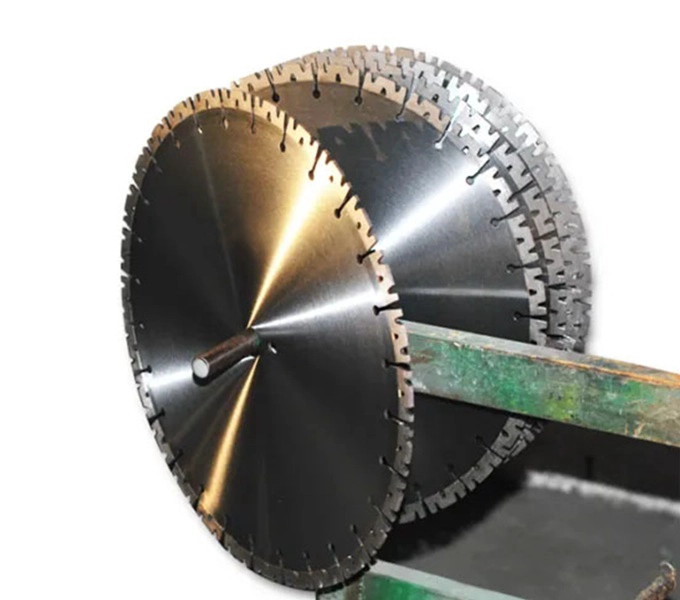

W Shape Edge Cutting Diamond Segment, High Frequency Welded Granite Cutting Segment

- Port: Xiamen

- Brand Name: Boreway

- Model Number: BW-DSEGB-04

- Type: Wet use only

- Service: OEM & ODM

- Blade Type: W Shape

- Cutting result: Flat surface and even size

- Transport Package: Packing in carton cases

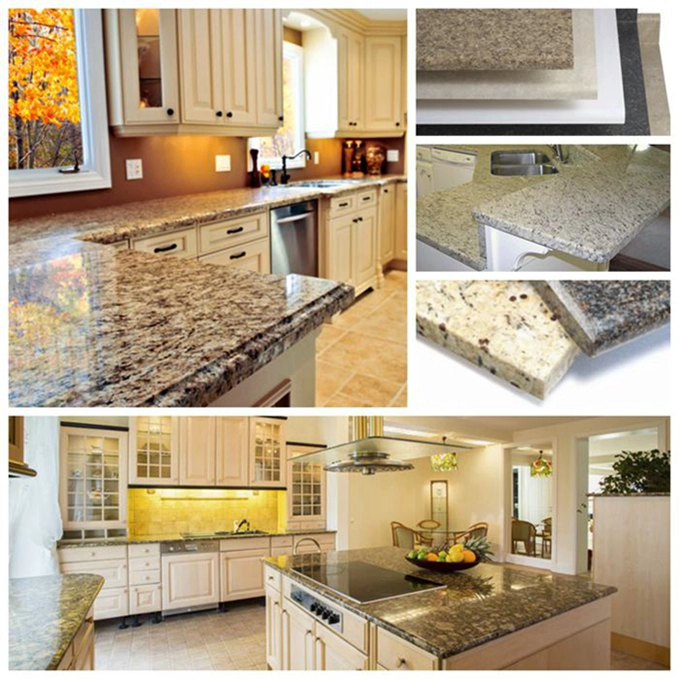

- Usage: Slab edge cutting of Granite, Sandstone, various hard stone with quartz

- Machine: Bridge Cutting Machine, Manual Handling Cutting Machine or Table Cutting Machine

| Descriptions: |

|

W Shape Edge Cutting Segment,High Frequency Welded Wet Use W Shape Granite Edge Cutting Diamond Segment:

Under same segment bond condition, short length means less resistance, Granite Edge Cutting Diamond Segment is good to reduce the cutting resistance from the stones, thus it help to improve the cutting speed. With the improving of the cutting speed, this design give very smooth cutting.

Such diamond segment are highest ratio of performance to price! |

| Specifications: |

| Granite Edge Cutting Segment Dimension | ||||

| Specification | Dimension of Segment(L*W*H) | No.of teeth | ||

| 300 | 40 | 3.0/3.2 | 8/10/12 | 21 |

| 350 | 40 | 3.0/3.2 | 8/10/12/15 | 24 |

| 400 | 40 | 3.4/3.6/3.8 | 8/10/12/15 | 28 |

| 450 | 40 | 4.0/4.2 | 8/10/12/15 | 32 |

| 500 | 40 | 4.0/4.2 | 8/10/12/15 | 36 |

| 600 | 40 | 4.6/4.8 | 8/10/12/15 | 42 |

| 700 | 40 | 5.5/5.2 | 8/10/12/15 | 42 |

| 800 | 40 | 6.0 | 8/10/12/15 | 46 |

| Product Details: |

| Applications: |

Cutting Effect:

| Advantages: |

| About us: |

| Packing & Delivery: |

| Our service: |

| FAQ: |

1). The RPM of the machine, the cutting object.

2). The detail picture of diamond segment after use, e.g. the cutting side of diamond segment.

3). Do you feed enough cooling water.

| Please note: |

| Contact us: |

No.605 Huahui Center, Shuitou Town 362342 Quanzhou, Fujian, China

No.605 Huahui Center, Shuitou Town 362342 Quanzhou, Fujian, China TEL: (+86)595-86990206 /

TEL: (+86)595-86990206 /  Fax: (+86)595-86990220

Fax: (+86)595-86990220 Mobile/WhatsApp/Wechat: (+ 86) 13559599186

Mobile/WhatsApp/Wechat: (+ 86) 13559599186 E-mail: boreway06@boreway.net

E-mail: boreway06@boreway.net Aaron Lin

Aaron LinTel:0086-595-86990206

Contact Person:boreway 06

PDF Show:PDF