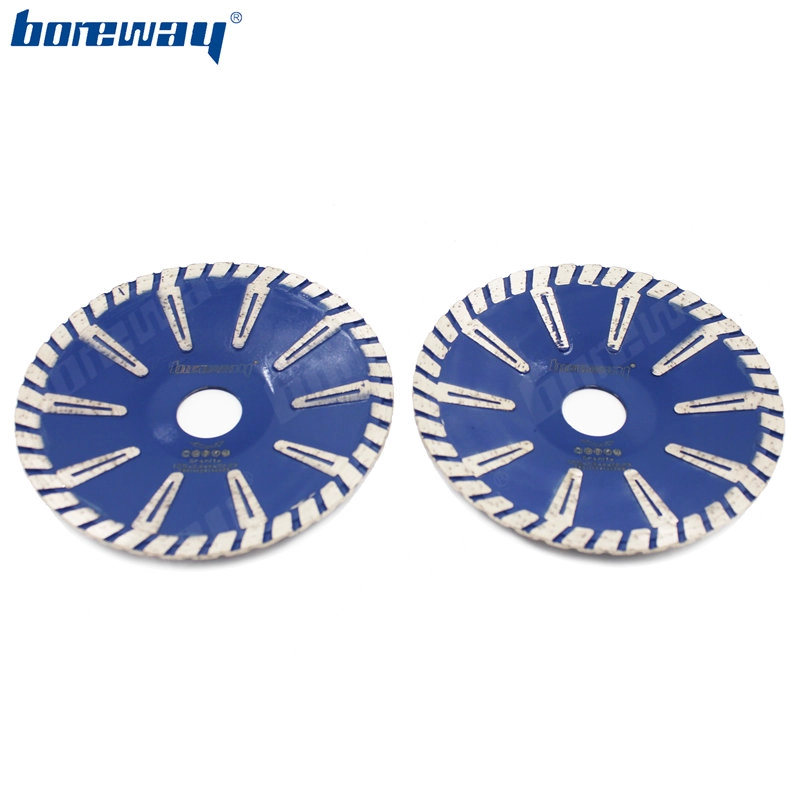

Boreway Fast Cutting 150mm T Segmented Concave Cutting Disc Diamond Circular 6 Inch BladStone Tile And Other Building Material

- Size:150mme

- Diameter:6 Inch

- Usage:Dry And Wet

- Brand Name:Boreway

- Segment Height:8mm

- Type:Concave Saw Blade

- Blade Material:Alloy Steel

- Model Number:BW-CSB-02-03

- Inner Diameter:20mm, 22.23mm

- Advantage:Long Life, Super Cutting Efficiency

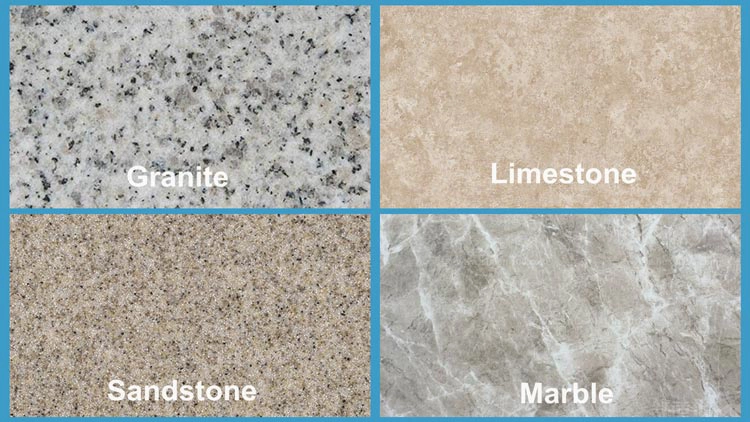

- Application:Marble, Granite And Sandstone Etc.

- Finishing:Anti Rust Oil, Gloss Oil And Spray Paint

- Package:Carton Box for Each Piece or Customers Requirement

Boreway Fast Cutting 150mm T Segmented Concave Cutting Disc Diamond Circular 6 Inch Blade For Smooth Brick Concrete Stone Tile And Other Building Material

1. Delivery on time

2. Our price is competitive

3.Accept small quantity orders

4.Produce all kinds of specifications

5.Long life and stable performance

6.Any package according to customers

7.Good cutting result and high efficiency

1.Sintered segment

3.For light or medium duty cutters

6.Designed to cutting brick/block, paves, concrete and stone.

| Feature: |

Fast Cutting T Segmented Cutting Disc

1. Delivery on time

2. Our price is competitive

3.Accept small quantity orders

4.Produce all kinds of specifications

5.Long life and stable performance

6.Any package according to customers

7.Good cutting result and high efficiency

| Description: |

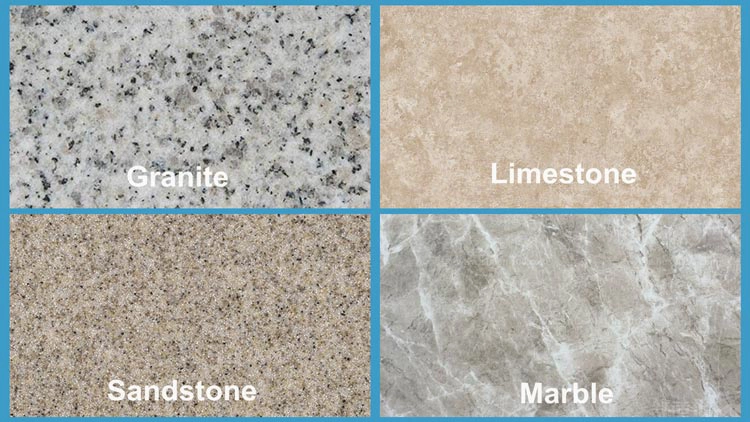

Fast Cutting T Segmented Cutting Disc faster cutting on kinds of Hard, Medium Hard, Soft Stone, like Granite, Marble, Sandstone, Limestone etc.

| Segment Height: | 8mm |

| Hole: | 22.23mm |

| Brand Name: | Boreway |

| Blade Material: | Alloy Steel |

| Size: | 6Inch,150mm |

| Type: | Sintered Saw Blade |

| Manufacture Method: | Sinter ( Hot Press / Cold Press) |

| Finishing: | Anti Rust Oil, Gloss Oil And Spray Paint |

| Application: | Stone, Marble, Granite, Concrete, Tile, Asphalt Etc. |

| Specification: |

The following are normal specifications Fast Cutting T Segmented Cutting Disc:

| Diameter | Bore (mm) | Segment Height |

| 105mm(4 inch) | 20mm/22.23mm | 8mm |

| 125mm(5 inch) | ||

| 150mm(6 inch) | ||

| 180mm(7 inch) |

The above specifications is only for reference, other specifications may be available as per customer's demand.

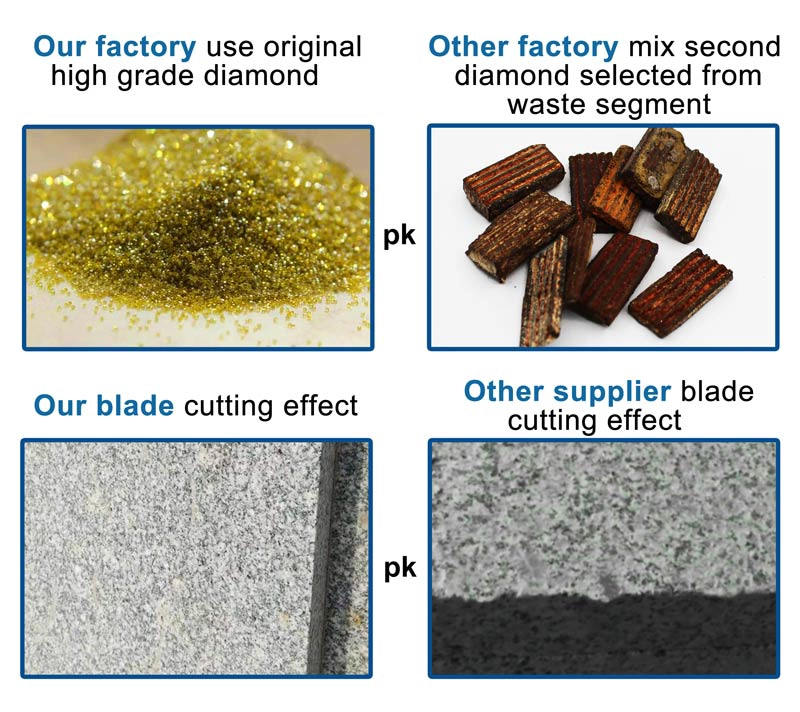

| Advantage: |

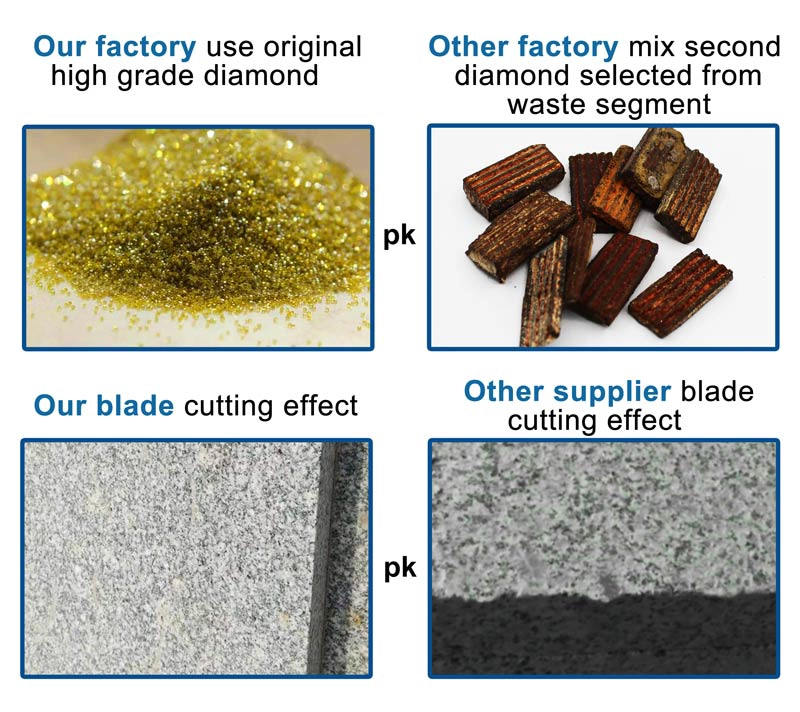

Fast Cutting T Segmented Cutting Disc

2.Delivers a fast, smooth cut

4.Can be used wet or dry. Wet use recommend

5.Basic quality diamond and economical cutting value

5.Basic quality diamond and economical cutting value

6.Designed to cutting brick/block, paves, concrete and stone.

Factory=Quality Control=Competitive Price=Own technology=OEM

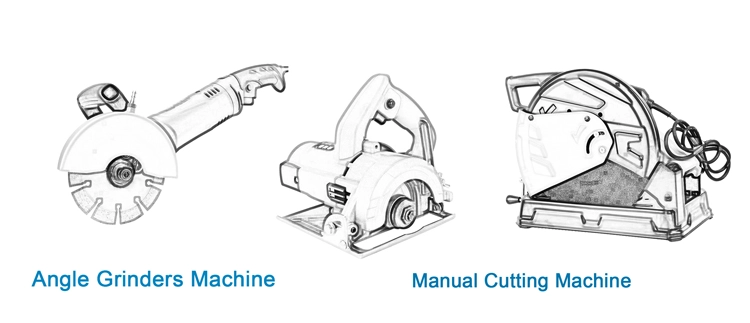

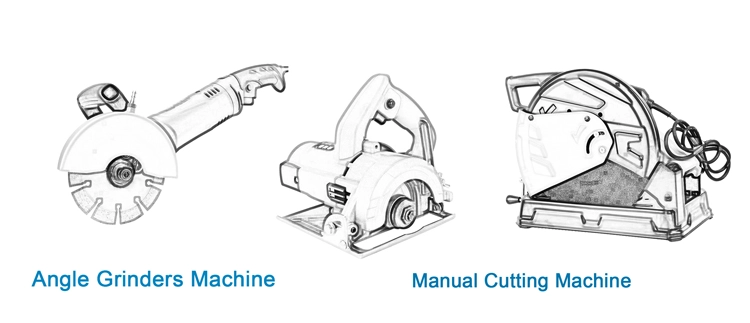

Fast Cutting T Segmented Cutting Disc is suitable for cutting hard, medium-hard and soft stones, such as granite, marble, sandstone and limestone. Suitable for all kinds of manual cutting machines or angle grinders.

1. Before saw blade installed, pollutions adhering between saw blade and flange shall be removed,

when installing saw blade, the marked direction shall be kept consistent with the rotating

direction of electric tools, and flange shall be fastened by spanner attached to electric tools.

2. Do not use any saw blade that has been deformed for being pressed of crashed.

3. When operating, operator must wear safety helmet, safety footwear and goggles, protective glove,additionally, if necessary operator must use earplug, mask and so on

4. Electric tools shall have protective cover.

No.605 Huahui Center, Shuitou Town 362342 Quanzhou, Fujian, China

No.605 Huahui Center, Shuitou Town 362342 Quanzhou, Fujian, China

TEL: (+86)595-86990206 /

TEL: (+86)595-86990206 /  Fax: (+86)595-86990220

Fax: (+86)595-86990220

Mobile/WhatsApp/Wechat: (+ 86) 1<

Mobile/WhatsApp/Wechat: (+ 86) 1<

| Application: |

Hot Sintered or Code Pressed, Dry or Wet Use!

Fast Cutting T Segmented Cutting Disc is suitable for cutting hard, medium-hard and soft stones, such as granite, marble, sandstone and limestone. Suitable for all kinds of manual cutting machines or angle grinders.

| Applications Machine: |

Fast Cutting T Segmented Cutting Disc f is used to cut round or arc-shaped wire plates for table protection. The cutting effect on both the inner and outer sides is also excellent.

Attention when use:

1. Before saw blade installed, pollutions adhering between saw blade and flange shall be removed,

when installing saw blade, the marked direction shall be kept consistent with the rotating

direction of electric tools, and flange shall be fastened by spanner attached to electric tools.

2. Do not use any saw blade that has been deformed for being pressed of crashed.

3. When operating, operator must wear safety helmet, safety footwear and goggles, protective glove,additionally, if necessary operator must use earplug, mask and so on

4. Electric tools shall have protective cover.

| Related Products: |

| About us: |

| Packing & Delivery: |

PS:

1.Tools packing in carton cases

2.By Air/Sea for batch goods, Airport/Port receiving

3.Less than 45kg, generally delivery by express(Door to Door)

4.When tools are in large quantities, they are packing in wooden cases

| Our service: |

1. Low order quantity: It can meet the test order you need.

2. Fast delivery: We get great discounts from freight forwarders.

3. OEM Acceptable: We can produce according to your samples or drawings.

4. Good quality: We have a strict quality control system. Has a good reputation in the market.

5. Good service: We regard our customers as God with a high degree of professionalism and enthusiasm.

| FAQ: |

1. If we want to order your product, how do we know your quality?

You can test with a small order, and then you will know the quality. Nowadays, many people in the world use Chinese products because of their high quality and high cost performance. We are a professional diamond tool manufacturer with more than 8 years of manufacturing experience.

2. Can you provide samples for free?

We do not provide free samples. Based on years of experience, we believe that customers will want them because of their reliable quality. By purchasing samples, we will cherish and appreciate them and make them get more. We are ready to offer our potential customers a special discount on samples. It's very important that you give us feedback, and we will appreciate it.

3. Does your company accept customization?

Of course, we accept customization. Including different colors, cutting objects, etc. We can also tag your own label and company brand. If you want us to make any new products for you, just send your products to us. Whether it's drawings or samples, we have the ability to produce the same products. We will not sell these products to others, only customers can get permission.

You can test with a small order, and then you will know the quality. Nowadays, many people in the world use Chinese products because of their high quality and high cost performance. We are a professional diamond tool manufacturer with more than 8 years of manufacturing experience.

2. Can you provide samples for free?

We do not provide free samples. Based on years of experience, we believe that customers will want them because of their reliable quality. By purchasing samples, we will cherish and appreciate them and make them get more. We are ready to offer our potential customers a special discount on samples. It's very important that you give us feedback, and we will appreciate it.

3. Does your company accept customization?

Of course, we accept customization. Including different colors, cutting objects, etc. We can also tag your own label and company brand. If you want us to make any new products for you, just send your products to us. Whether it's drawings or samples, we have the ability to produce the same products. We will not sell these products to others, only customers can get permission.

| Please note: |

Please use high frequency Silver Welded machine instead of Fire to make the brazing, the welding time is only a few seconds, otherwise the diamond inside the segments will probably be damaged by the high temperature, then the cutting performance will be Reduced!

| Contact us: |

No.605 Huahui Center, Shuitou Town 362342 Quanzhou, Fujian, China

No.605 Huahui Center, Shuitou Town 362342 Quanzhou, Fujian, China TEL: (+86)595-86990206 /

TEL: (+86)595-86990206 /  Fax: (+86)595-86990220

Fax: (+86)595-86990220 Mobile/WhatsApp/Wechat: (+ 86) 1<

Mobile/WhatsApp/Wechat: (+ 86) 1<

Fujian Nan’an Boreway Machinery Co., Ltd.

Tel:0086-18650679939

Contact Person:Dora Zhang

PDF Show:PDF