Boreway Granite Manufacturer 2200mm Sintered Diamond Blade

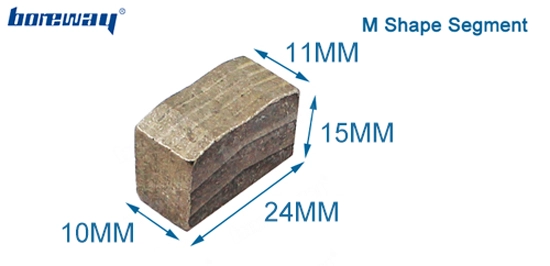

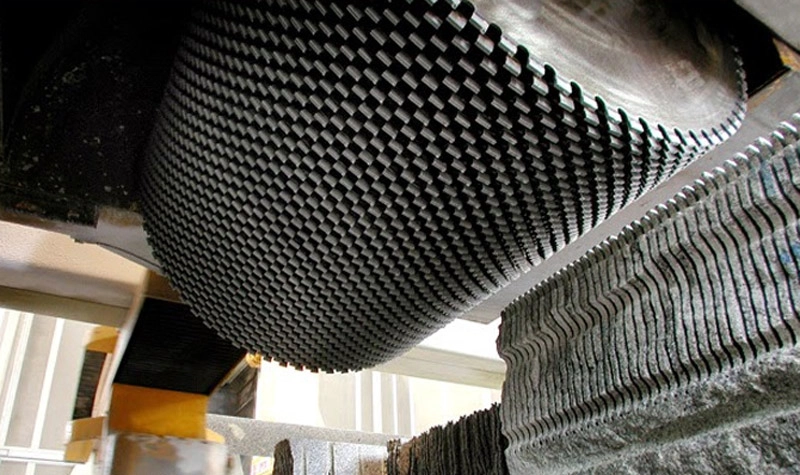

- Shape: M shape

- Usage: wet use

- Product Numbers: 132

- Opening: 100 / 120mm

- Brand Name: Boreway

- Disc diameter: 2200mm

- Model: BW-DSGB-12-17

- Material: diamond, cobalt, nickel, etc.

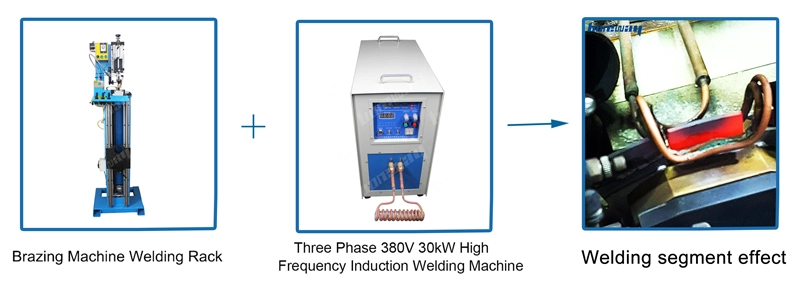

- Welding method: silver welding

- Origin: Fujian, China

- Segment size (L * W * H): 24x11 / 10x15m

- Welding method: high frequency welding machine for silver welding.

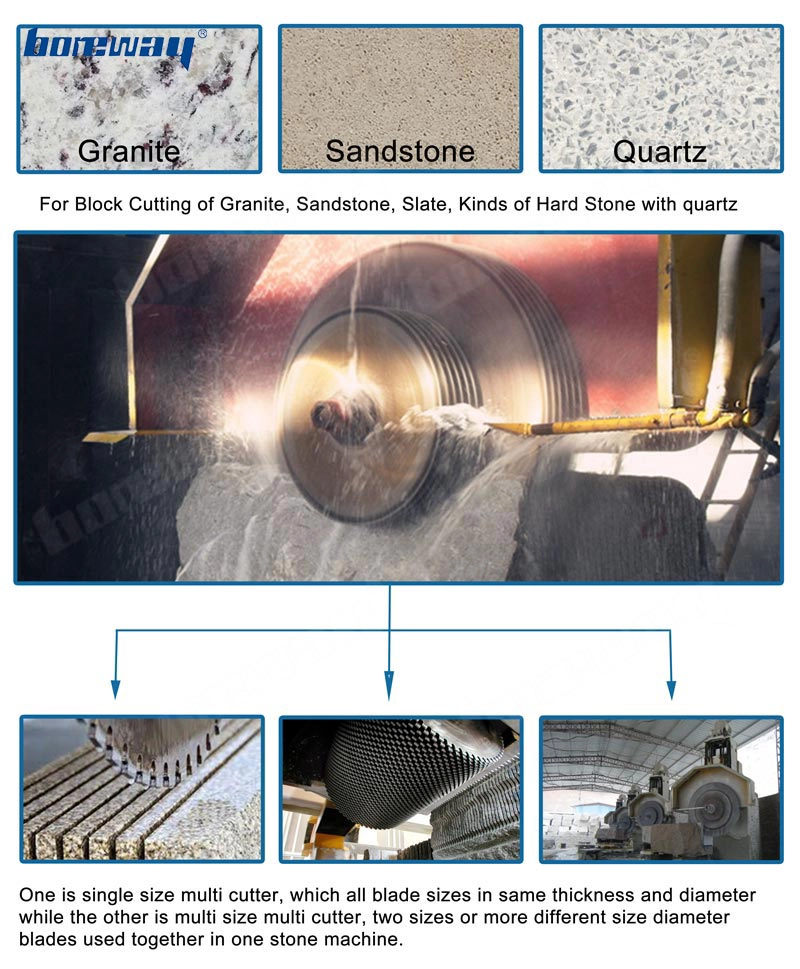

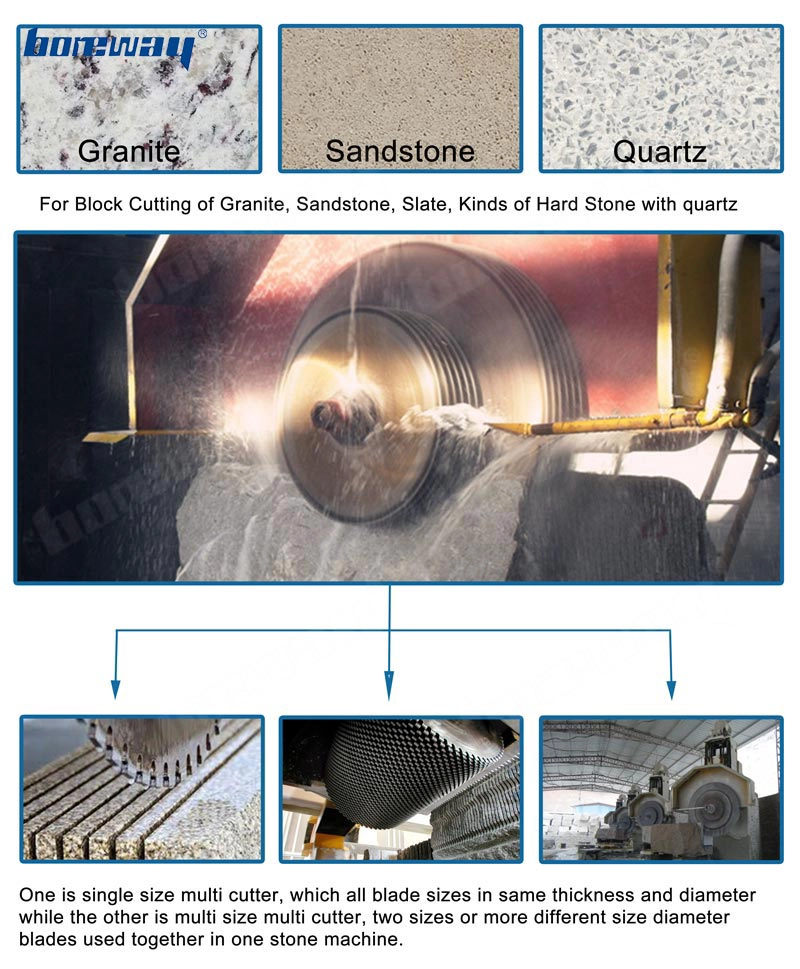

- Application: Cutting granite, sandstone, hard rock with quartz.

Boreway Granite Manufacturer 2200mm Sintered Diamond Blade

|

advantage:

|

2) The sharpness of the tool is good, the cutting speed is fast, and the cutting efficiency is high.

3) Good wear resistance, long service life, high cost performance and high integration.

4) Fast cutting, cutting, and splicing cut the stone surface to be smooth and uniform in size.

|

feature:

|

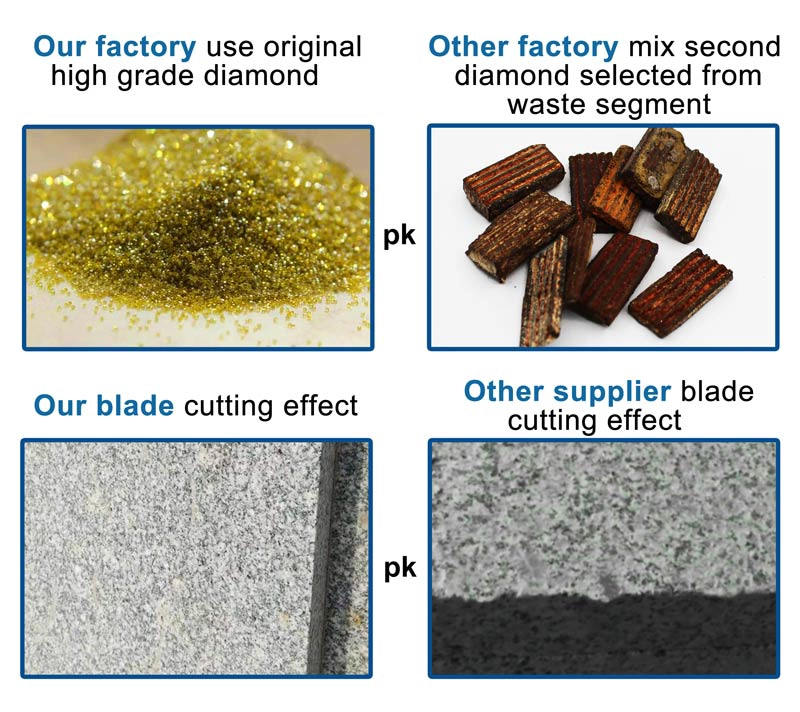

2) 2200mm sintered diamond bladeThe feeding of the diamond sheet forms a chemical bond with (Ti + Cr + Ni + Co, etc.), which can reduce threshing, improve the cutting edge, and extend the service life.

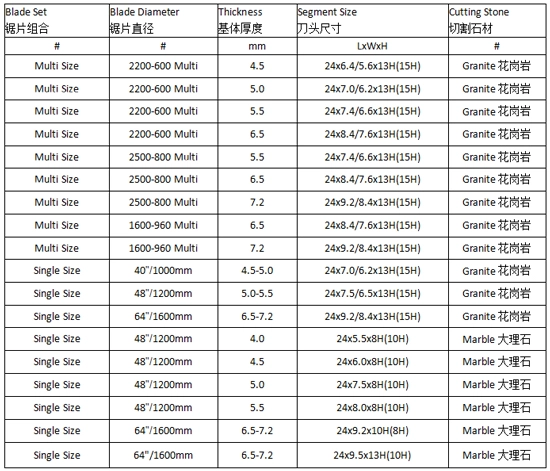

| specification: |

Following are the normal specifications 2200mm sintered diamond blade :

| Diameter mm | Thickness mm |

Number of teeth (number) | long | width | high | Hole (mm) | Speed |

| 2200 mm, 86 inches | 8.0 (9.0) |

132 | twenty four |

11.0 / 10.0 | 15/20 | 100/120 | 400 |

The above specifications are for reference only, other specifications can be provided according to customer requirements.

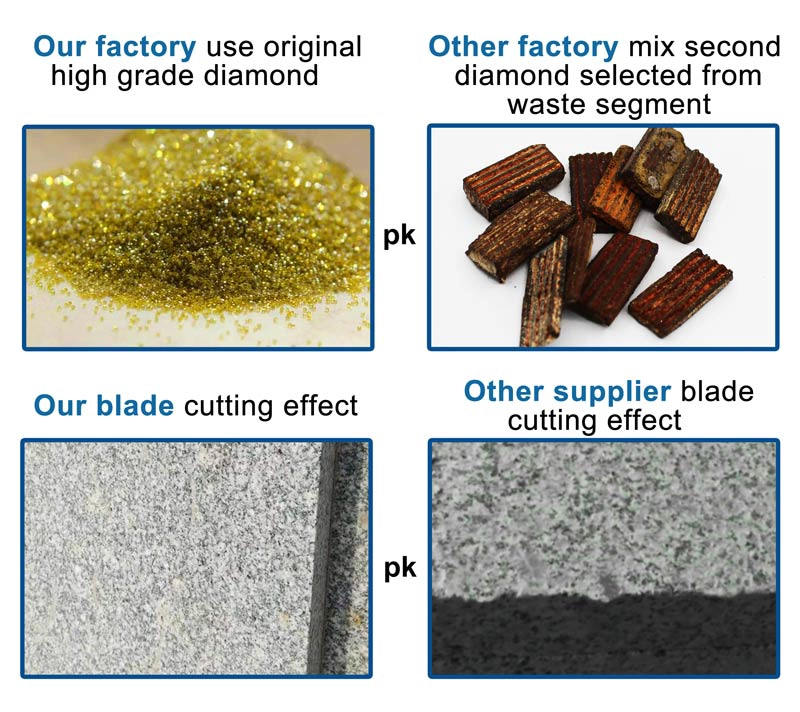

Factory = Quality Control = Competitive Price = Own Technology = OEM

When cutting, add some water to the cutting tool and let the water flow to make it have better cooling effect.

Otherwise, the speed of the compound saw blade is required to be 280-320 revolutions per minute, so the car speed is too fast!

| Product Details: |

example:

The stone is soft and abrasive, so we will use hard blades. Reinforced concrete with river pebble aggregate is hard, so we will use soft bonding blades.

Sandwich section of 2.5mm fast cutting saw blade

The stone is soft and abrasive, so we will use hard blades. Reinforced concrete with river pebble aggregate is hard, so we will use soft bonding blades.

Sandwich section of 2.5mm fast cutting saw blade

Hard bond

This means that the composition of the metal forms about 105 to 120 HRB (hardness) fragments when sintered together, and is very resistant to soft abrasive sawing, thus releasing diamond at an appropriate rate.

Hard bonds usually consist of the following metal powders: cobalt, iron, tungsten carbide, and gray to dark gray.

This means that the composition of the metal forms about 105 to 120 HRB (hardness) fragments when sintered together, and is very resistant to soft abrasive sawing, thus releasing diamond at an appropriate rate.

Hard bonds usually consist of the following metal powders: cobalt, iron, tungsten carbide, and gray to dark gray.

Soft bond

This means that when sintered together, the accumulation of metal forms a segment of about 90 to 105 HRB (hardness) and causes the segment to wear faster, leaving the diamond on the cutting surface.

Soft keys usually consist of the following metal powders-copper, bronze and cobalt, usually bronze to light silver.

This means that when sintered together, the accumulation of metal forms a segment of about 90 to 105 HRB (hardness) and causes the segment to wear faster, leaving the diamond on the cutting surface.

Soft keys usually consist of the following metal powders-copper, bronze and cobalt, usually bronze to light silver.

| Application: |

Diamond tablets cut granite, sandstone, various hard quartz stones.

2200mm sintered diamond blade can only be used wet

No.605 Huahui Center, Shuitou Town, Quanzhou City, Fujian Province 362342

No.605 Huahui Center, Shuitou Town, Quanzhou City, Fujian Province 362342

phone: (+86) 595-86990206 /

phone: (+86) 595-86990206 /  fax: (+86) 595-86990220

fax: (+86) 595-86990220

Phone / WhatsApp / WeChat: (+ 86) 18650679939

Phone / WhatsApp / WeChat: (+ 86) 18650679939

Zhang Lyon

Zhang Lyon

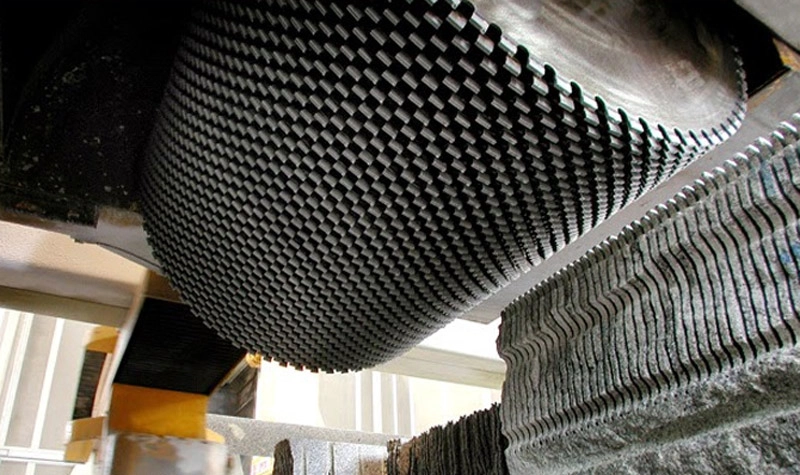

| Application machine: |

2200mm sintered diamond bladeFor single or multiple circular saws from 900 mm to 3500 mm, cutting granite, sandstone, various quartz hard stones

1. If the material is hard, the bonding of the diamond segments should be soft.

Because diamonds become dull when cutting hard materials. Softer

The duller diamonds wear out faster, then it is easier to expose new diamonds underneath to participate in cutting

Because diamonds become dull when cutting hard materials. Softer

The duller diamonds wear out faster, then it is easier to expose new diamonds underneath to participate in cutting

2. If the material is relatively soft, the bond should be hard.

Diamonds can last longer in this case. The harder binding layer wears more slowly, so it can hold the diamond longer. This makes better use of diamond and extends the life of diamond tools.

| Application machine: |

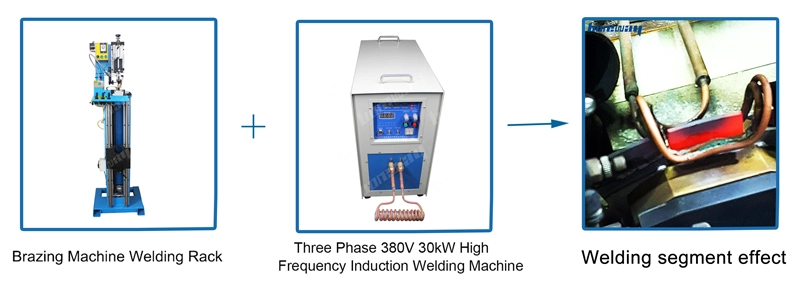

Welding method: 2200mm sintered diamond bladeHigh frequency welding machine for silver welding

It is recommended to use high frequency silver welding machine instead of welding with fire.Do not weld the diamond sheet for a long time, only a few minutes, otherwise the internal diamond may be damaged due to high temperature, which will greatly affect the cutting performance of the granite sheet.

| about us: |

| our service: |

1. Low order volume: can meet your required test orders.

2. Fast delivery: We get a great discount from the freight forwarder.

3. OEM acceptable: We can produce according to your samples or drawings.

4. Excellent quality: We have strict quality control system. Has a good reputation in the market.

5, Excellent service: We treat customers as God with a high degree of professionalism and enthusiasm.

2. Fast delivery: We get a great discount from the freight forwarder.

3. OEM acceptable: We can produce according to your samples or drawings.

4. Excellent quality: We have strict quality control system. Has a good reputation in the market.

5, Excellent service: We treat customers as God with a high degree of professionalism and enthusiasm.

| FAQ: |

1. If we want to order your product, how do we know your quality?

You can order in small quantities for testing and you will know the quality. Today, many people in the world use Chinese products for their high quality and cost-effectiveness. We are a professional diamond tool manufacturer with more than 8 years manufacturing experience.

2. Can you provide samples for free?

We do not provide free samples. Based on years of experience, we believe customers will want them for their reliable quality. By buying samples, we will cherish and appreciate them and make them more. We are ready to offer special discounts for samples to potential customers. Your feedback is very important and we would appreciate it.

3. Does your company accept customization?

Of course, we accept customization. Including different colors, cutting objects and more. We can also mark your own label and company brand. If you want us to make any new product for you, just send us your product. Whether it is drawings or samples, we have the ability to produce the same product. We do not sell these products to others and only customers can obtain a license.

You can order in small quantities for testing and you will know the quality. Today, many people in the world use Chinese products for their high quality and cost-effectiveness. We are a professional diamond tool manufacturer with more than 8 years manufacturing experience.

2. Can you provide samples for free?

We do not provide free samples. Based on years of experience, we believe customers will want them for their reliable quality. By buying samples, we will cherish and appreciate them and make them more. We are ready to offer special discounts for samples to potential customers. Your feedback is very important and we would appreciate it.

3. Does your company accept customization?

Of course, we accept customization. Including different colors, cutting objects and more. We can also mark your own label and company brand. If you want us to make any new product for you, just send us your product. Whether it is drawings or samples, we have the ability to produce the same product. We do not sell these products to others and only customers can obtain a license.

| Please note: |

Please use a high-frequency silver welding machine instead of a furnace for brazing. The welding time is only a few seconds, otherwise the diamond in the segment may be damaged by high temperature, which will reduce the cutting performance!

| contact us: |

No.605 Huahui Center, Shuitou Town, Quanzhou City, Fujian Province 362342

No.605 Huahui Center, Shuitou Town, Quanzhou City, Fujian Province 362342 phone: (+86) 595-86990206 /

phone: (+86) 595-86990206 /  fax: (+86) 595-86990220

fax: (+86) 595-86990220 Phone / WhatsApp / WeChat: (+ 86) 18650679939

Phone / WhatsApp / WeChat: (+ 86) 18650679939  Zhang Lyon

Zhang Lyon

Fujian Nan’an Boreway Machinery Co., Ltd.

Tel:0086-18650679939

Contact Person:Dora Zhang

PDF Show:PDF