What is the role of the bond in the saw blade?

Matrix binder plays a role in fixing diamond.

The adhesive for fixing diamond particles in the blade is formed from a mixture of metal powders. Different metal powders are combined in a specific proportion to achieve a specific wear rate.

The correct wear rate will ensure that the diamond particles remain in place long enough to achieve maximum wear. Then they will release them, exposing the next layer of diamond particles below.

The fast wearing soft adhesive is composed of soft metal powders such as bronze. These are the best choice for cutting materials such as ceramics and porcelain. These materials are very hard but have low abrasiveness.

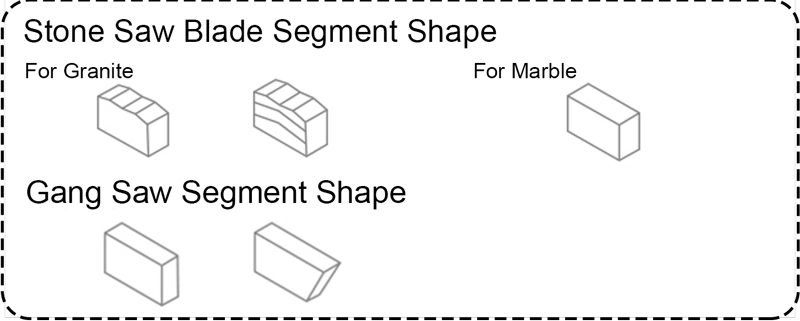

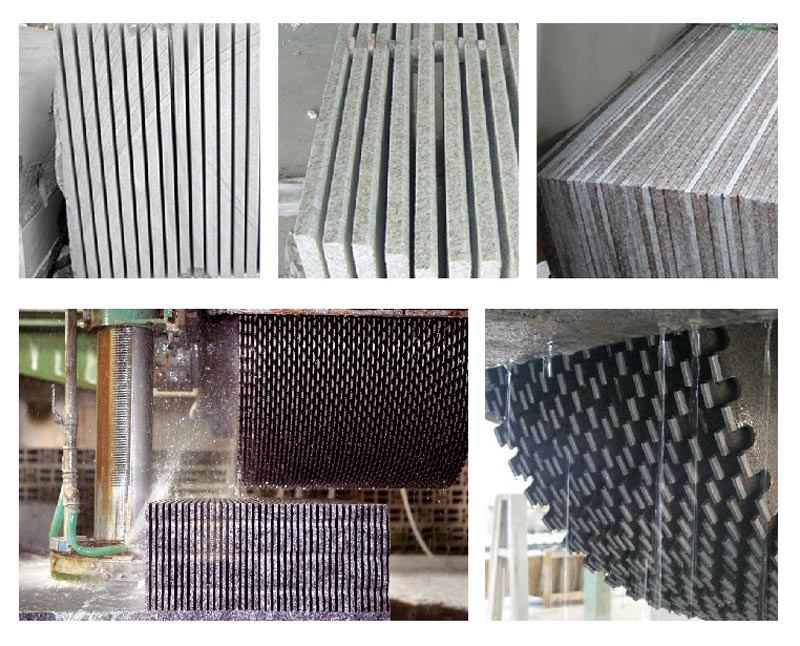

Diamond segments from professional supplier,the defense market requires different quality and sizes. we can create all types of size and quality or price according to your requirement.

The hard key with slow wear is composed of hard metals such as tungsten carbide. These materials are best suited for cutting materials such as asphalt, which is usually soft but abrasive.

Remember, opposites attract; For hard but low abrasive materials, it is better to use a soft adhesive. Vice versa, for soft but more abrasive materials, the harder the bonding effect is the best.

M shape diamond segment for single blade.It is mainly applied for edge cutting, chamferring and pocessing various of types of granite slabs. Its special design can enhance the cutting shrpness and achieve long working lifespan.