How many common cutting methods are there?

Dora Zhang

2022-07-11 12:26:55

There are two common cutting methods: wet cutting and dry cutting

Wet cutting is the most commonly used method. 125mm turbo rim dry wet cutting disc can reduce the heat generated during cutting and prolong the service life of the saw blade by adding water.

Any dry blade can be used wet, however, a wet blade cannot be used dry. Even a few seconds of dry cutting is sometimes enough to damage the wet blade.

The use of water helps to reduce the heat generated by friction, especially on abrasive materials, so as to prevent the blade from overheating, thereby extending the life of the diamond blade.

Overheating will lead to blade cracking and premature loss of blade segments. In addition, when there is too little coolant, chips (fine particles) are not removed from the notch quickly enough, which may lead to edge collapse.

Ideally, dry cutting should be used only when the area needs to be kept dry or when power tools are being used, which makes it unsafe to use water around the power supply.

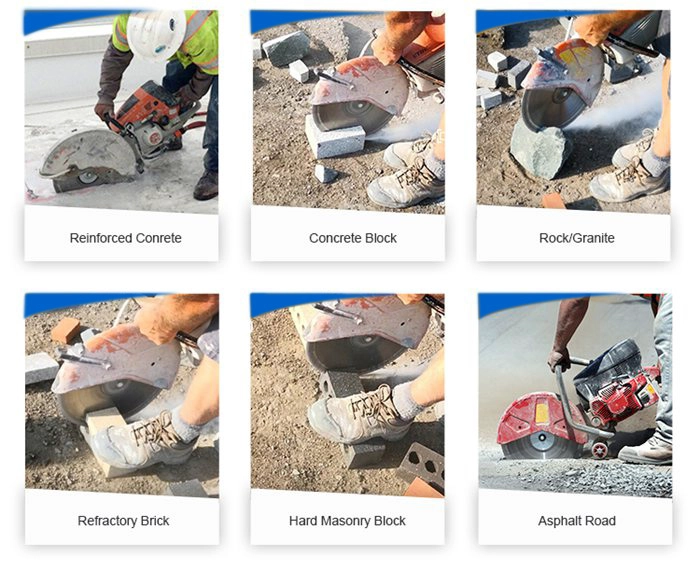

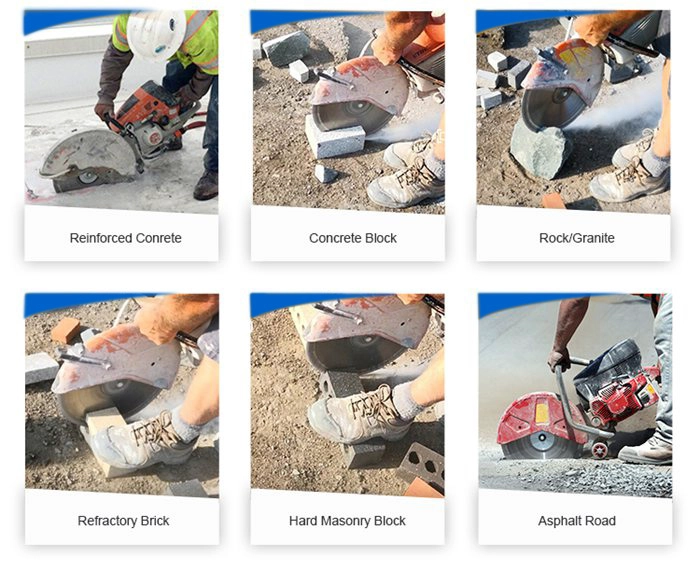

Diamond saw blades for reinforced concrete,for bridge cutting machine, manual handling cutting machine, table cutting machine.

The fine dust generated during dry cutting on bricks, glass and other hard materials poses a potential safety hazard to people nearby.

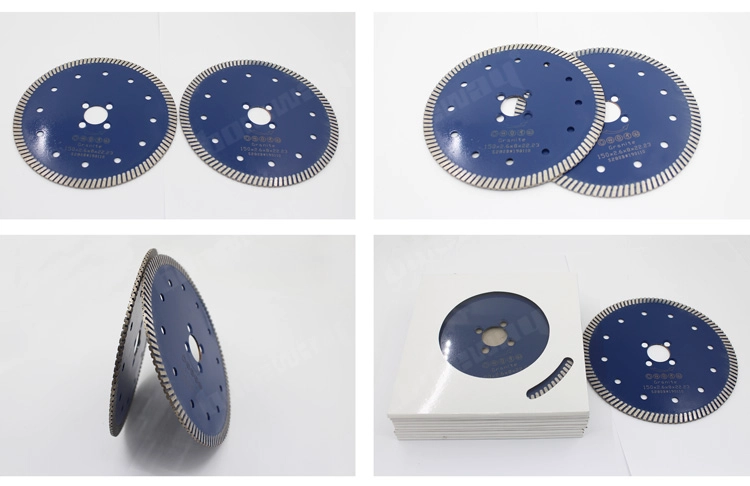

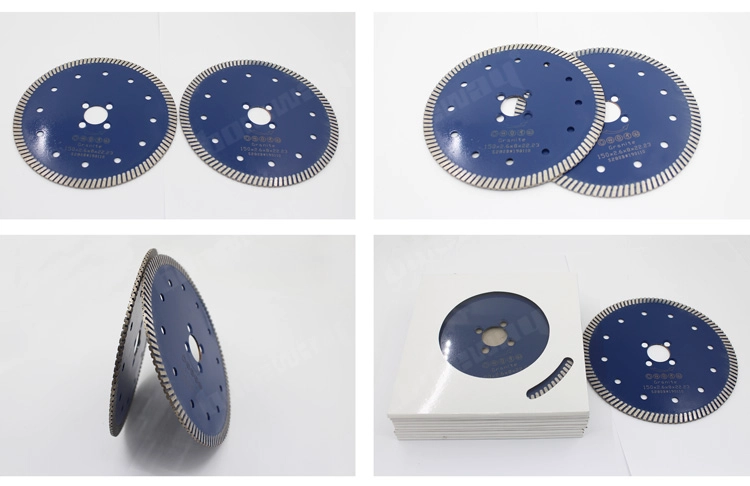

Factory price narrow turbo cutting saw blade for cutting ceramics, porcelain, vitrified tiles, granite, stoneware, hard tiles and other stone.

Water helps to reduce the amount of dust generated. If you are dry cutting, it is best to do it outdoors and use vacuum accessories. It is also important to let the diamond blade rotate freely outside the cutting and cool it regularly.

Always wear a dust mask when dry cutting to prevent inhalation of dust, which may lead to serious lung disease.

Wet cutting is the most commonly used method. 125mm turbo rim dry wet cutting disc can reduce the heat generated during cutting and prolong the service life of the saw blade by adding water.

Any dry blade can be used wet, however, a wet blade cannot be used dry. Even a few seconds of dry cutting is sometimes enough to damage the wet blade.

The use of water helps to reduce the heat generated by friction, especially on abrasive materials, so as to prevent the blade from overheating, thereby extending the life of the diamond blade.

Overheating will lead to blade cracking and premature loss of blade segments. In addition, when there is too little coolant, chips (fine particles) are not removed from the notch quickly enough, which may lead to edge collapse.

Ideally, dry cutting should be used only when the area needs to be kept dry or when power tools are being used, which makes it unsafe to use water around the power supply.

Diamond saw blades for reinforced concrete,for bridge cutting machine, manual handling cutting machine, table cutting machine.

The fine dust generated during dry cutting on bricks, glass and other hard materials poses a potential safety hazard to people nearby.

Factory price narrow turbo cutting saw blade for cutting ceramics, porcelain, vitrified tiles, granite, stoneware, hard tiles and other stone.

Water helps to reduce the amount of dust generated. If you are dry cutting, it is best to do it outdoors and use vacuum accessories. It is also important to let the diamond blade rotate freely outside the cutting and cool it regularly.

Always wear a dust mask when dry cutting to prevent inhalation of dust, which may lead to serious lung disease.